Here, bigHead Bonding Fasteners outlines its composite fastening solutions to the rail industry, providing components which are reliable, reduce operating costs as well as vehicle weight.

Rail industry OEMs face considerable pressures on all fronts. In rolling stock manufacture, companies are striving to achieve overall weight reductions of around 30% in order to meet their goals in terms of sustainability, operating cost reductions, capacity and efficiency. Vehicle weight reduction will be a significant part of the response to these challenges.

A large part of rail vehicle weight reduction will be determined by the materials and construction methods used, driving the industry to look at new materials and production processes. Two materials that consistently stand out above the rest in ability to satisfy design and structural criteria are fibre-reinforced polymer composite (FRP) materials and honeycomb or foam laminates. Composites made from recycled composites are proliferating making sustainability more apparent for this material.

“When customers move from metal to composites, as a consequence of light-weighting or for reasons of performance or design enhancement, they discover a lack of guidance or knowledge in fastening composites. Whether they are designing, manufacturing or assembling with composite material this inexperience can be a major hurdle. There is little or no time to experiment and try things out,” explains the company. bigHead undertake R&D at its premises on the Cranfield University Technology Park to create optimal solutions for composites which are notoriously prone to non-standardisation.

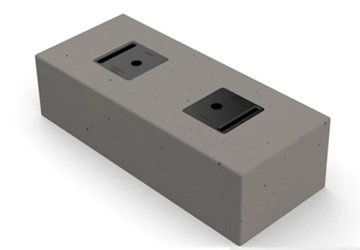

bigHead fasteners can be embedded in the composite materials during the lay-up process or surface bonded with adhesive. Both of these discrete and secure solutions facilitate fast and trouble-free mounting while removing the need for secondary assembly processes – helping to reduce manufacturing costs for fabricating lightweight composites.

Working with Tier 1 suppliers to UK and European train builders, bigHeads are being used in a variety of applications where secure, discrete bigHeads are suitable, including front cabs, passenger and bathroom modules. The fasteners are secured in position utilising various male or female threaded fasteners that allow fixing without the need to drill through or provide access apertures in the composite material.

bigHead fasteners are also contribuiting towards sustainability. Reducing the weight of new trains is the single most cost-effective intervention the rail industry can make as it seeks to reduce its CO2 emissions, according to the Rail Safety and Standards Board (RSSB). This body estimates that the additional capital costs from moving to light-weight vehicles will give more than two times pay back over the lifetime of the train.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.