With the MCA power clamping nut from JAKOB Antriebstechnik, the user has at his disposal a long proven, widely used and economical clamping element which can ensure the highest clamping forces and maximum operational reliability - and is easy to operate manually.

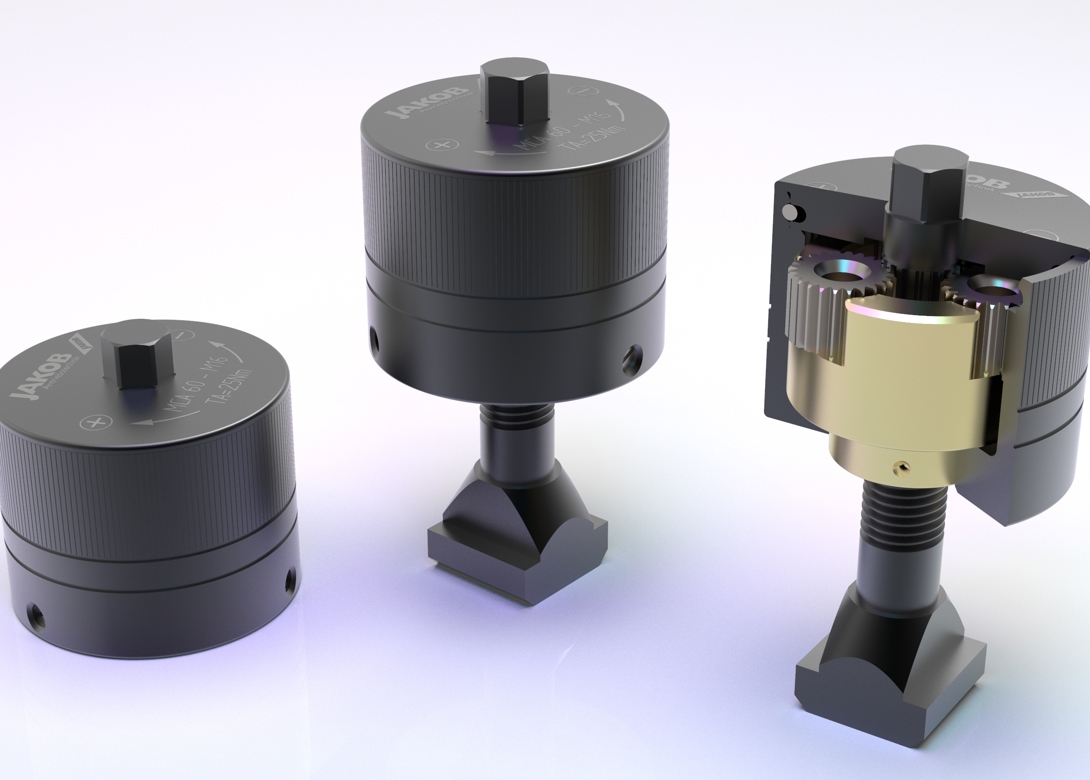

For this only a wrench SW 17 is required. Nevertheless, it is recommended to use a torque wrench to set exact, reproducible tightening torques. The special inner life, an integrated planetary gear mechanics, multiplies the manual tightening torque.

Their durability has been proven on a specially designed test bench. They were subjected to a continuous load of 10,000 load changes and were able to confirm all expectations.

The power clamping nut MCA is based on the predecessor model MC. Externally, the changed design and the reduced external dimensions are striking first. But also in the inner life a lot has changed. The bearing of the planetary gears is now accomplished by stable claws instead of bolts. This made room for significantly larger screw threads and increased the performance range by up to 100%.

The material made of tempered steel and the surface coating that protects against corrosion guarantee a long service life of the clamping elements. The tightness of the drive mechanism and splash protection could also be increased. The MCA mechanical clamping nut is maintenance free under normal operating conditions and can be used in special versions up to 400°C.

The power clamping nuts are used in all areas of mechanical engineering where large clamping forces are required. For example, the economic clamping of press and punching tools or workpiece clamping during machining. But also in steel and jig construction there are universal application areas.

The series MCA is available with clamping screws from M12 to M64 and with clamping forces up to 200kN in the standard program.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.