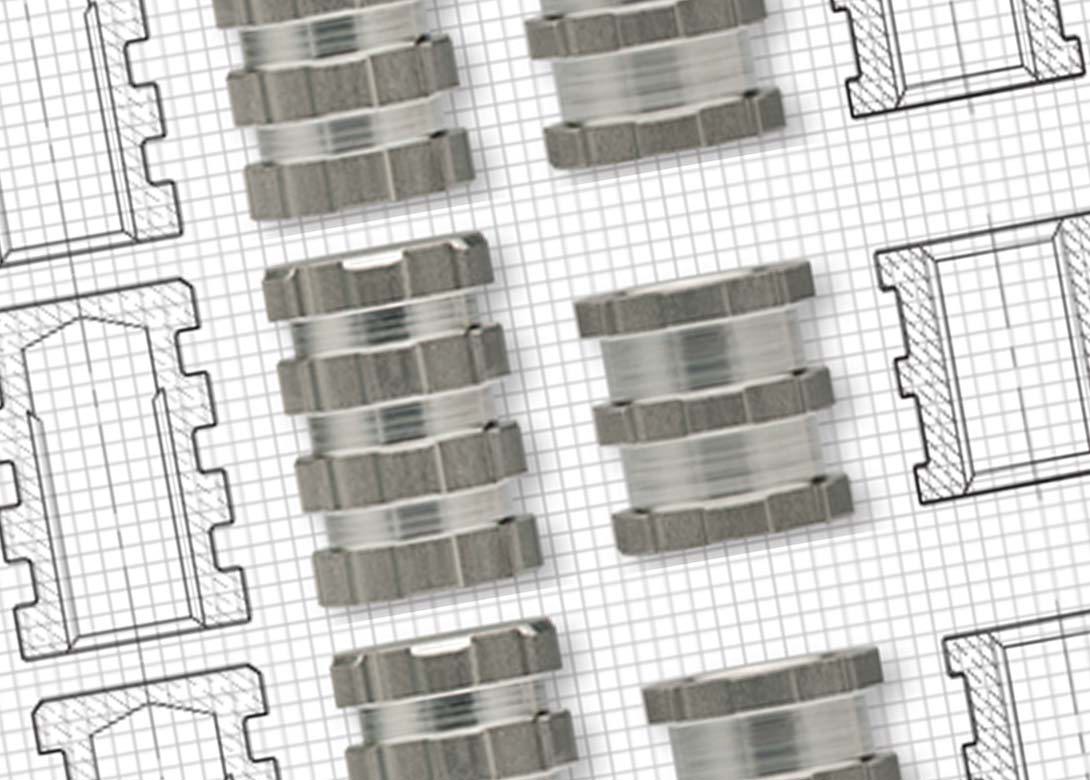

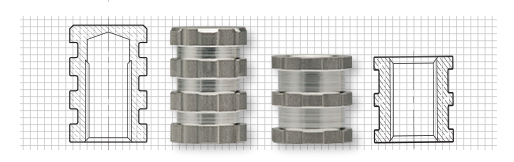

SPIROL has introduced a high-performance line of Moulded-In inserts for plastics manufactured from aluminium. The design of the Series 60 Blind-End and Series 61 Through-Hole inserts consists of axial grooves to maximise torque resistance, balanced with radial undercuts to achieve high-pull out force. These Moulded-In inserts are designed to be placed in the mould cavity prior to plastic injection and offer exceptional performance due to unrestricted plastic flow into the retention features on the outside diameter of the inserts.

The lightweight threaded inserts are manufactured from 2024 grade aluminium, which provides a combination of strength, corrosion resistance, machineability and cost effectiveness. Series 60 and Series 61 are lead free as well as 40% stronger than the same insert manufactured from brass, but a third of the weight. Standard inch thread sizes include 8-32, 10-24, 1/4-20, and 5/16-18, and M4, M5, M6, and M8 for metric thread sizes.

Both the Series 60 and Series 61 aluminium inserts have a patent pending on their design.

SPIROL offers a comprehensive line of inserts for plastics including Press-In, Expansion, Self-Tapping, Heat/Ultrasonic and Moulded-In styles to accommodate specific performance and installation requirements. From the design stage, SPIROL suggests involving its Application Engineers to recommend the most appropriate and cost-effective insert for all plastic assembly applications.

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.