A stainless steel thread insert is conquering the world. 65 years ago, Böllhoff started producing a product which, like no other, substantially influenced the rise of the family business: HELICOIL. Today, the product brand is world famous and a leader in thread inserts in the US, Latin America and Europe.

65 years of HELICOIL – that is 65 years of innovations around a high-tech product. However, during all those years, the heart of the functionality has remained unchanged. Then, as now, the thread insert has been creating high strength joints in low strength materials such as aluminium, magnesium and fibre-reinforced plastics like carbon fibre composites. For increased quality and value – whether for thread reinforcement or repair.

Since 1954, designs, diversity of variants as well as assembly systems have been continuously optimised and adapted to fit demanding applications.

Today, the name HELICOIL stands for a high-tech product family featuring long-lasting wear resistance, high surface quality, corrosion and high temperature resistance as well as economic processing during series production.

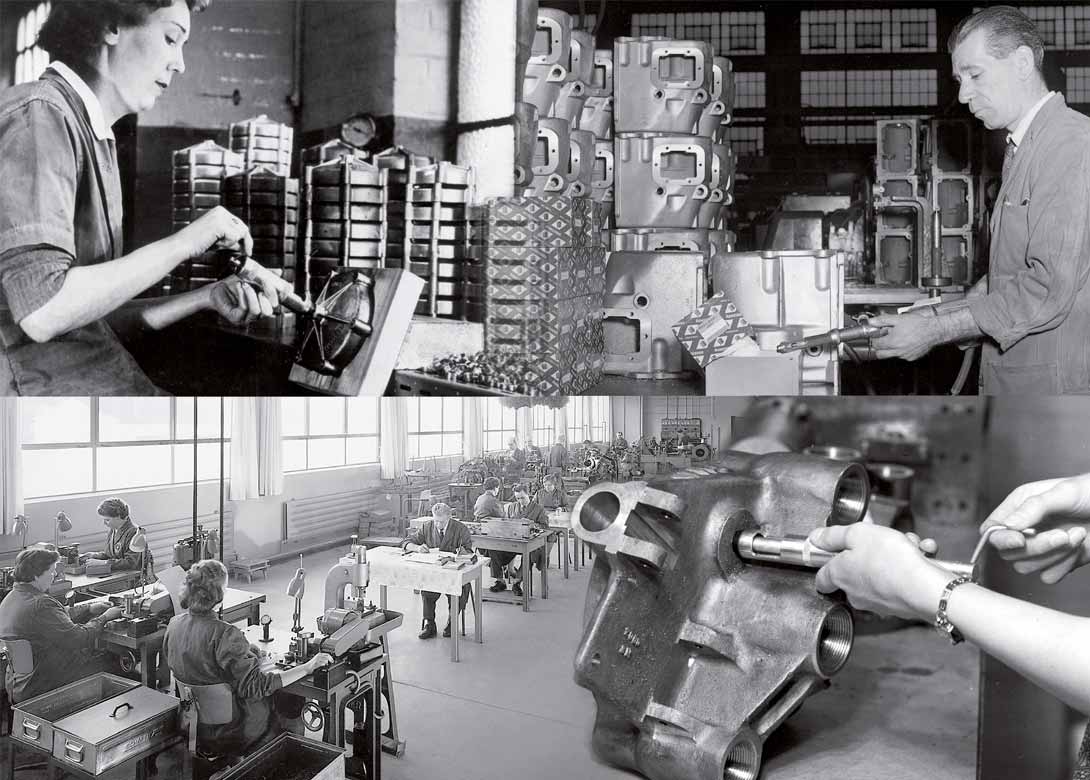

Radial engines for aircrafts made from grey cast iron showed high wear on screw joints. Those engines, already back in 1938, had been the incentive to develop the thread reinforcements which were patented as HELICOIL. Since 1954, Böllhoff produced the HELICOIL thread insert under licence. A step with many others to follow in that same direction, since in 1954 the family business set up their own production. Until then, the company had only been involved in the wholesale trade.

Inside the industry

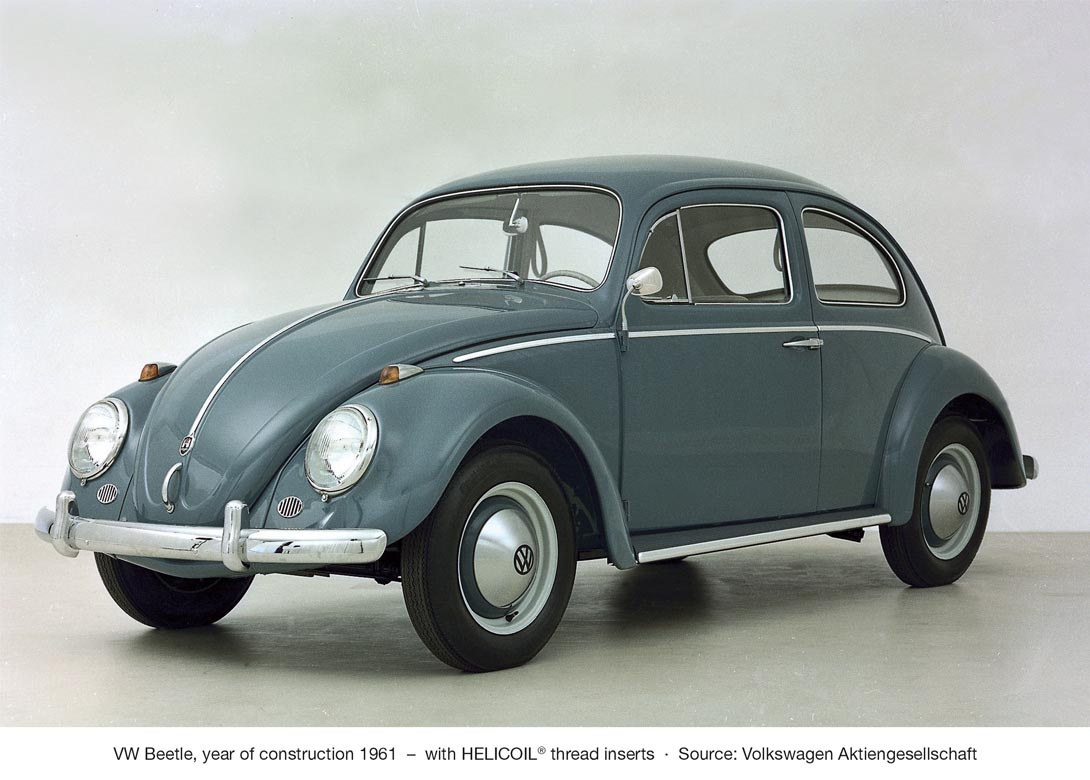

Volkswagen was among the very first customers. For the manufacture of the VW Beetle, for example, HELICOIL was used to reinforce the threads on the engine. Still today, the automotive industry continues to be an important customer group for that product. In that industry, the HELICOIL is primarily used in lightweight materials (magnesium, aluminium), while it has also proven to be a good choice for e-mobility.

Another important sector is mechanical engineering. Böllhoff is a partner of nearly every large press manufacturer. All aircraft manufacturers are HELICOIL customers. No modern aircraft is taking off without this thread insert – be it in the engines, in the interior or in the landing gear.

Highest quality requirements are also made in the field of medical engineering. HELICOIL is for example used in dialysis pumps and X-ray apparatuses. In aluminium housings of gearboxes, mobile phone electronics, high-quality object illumination and also in the semiconductor industry, HELICOIL thread inserts create corrosion and wear resistant threads.

Driving innovation

As a market leader, HELICOIL is at the same time a pioneer when it comes to fulfilling industrial requirements. That is why, early on, the development teams at Böllhoff have optimised the thread inserts to become corrosion and temperature resistant. The HELICOIL Screwlock was the first thread insert on the market to lock the screw so as to prevent self-unscrewing. Since there is no more need to lock the joint with additional split pins, installation and removal times and thus costs are reduced.

The further development of the HELICOIL Classic version led to the HELICOIL Plus Free Running version, which is easier to install. The next innovation level was reached by introducing the HELICOIL Tangfree technology. In combination with the adapted installation tools, it is a perfect addition to the product family.

Böllhoff never loses sight of economic efficiency so that the assembly systems for the HELICOIL product family are constantly being further developed as well. With high flexibility and fast and reliable processing, the solutions of the most recent generation create considerable potential for rationalisation. The range of installation tools stretches from the hand tool to automation.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.