Here Airedale Springs, an internationally renowned spring manufacturer that designs, tests and produces bespoke wire forms and custom springs for various applications, reviews the important role that springs play in the robotics sector and how the UK’s manufacturing industry is fully embracing industry trends, leveraging robotics and AI to benefit industries and the overall economy.

In a constantly improving technological landscape, it is impossible to downplay the role of robotics and artificial intelligence (AI) in manufacturing. These automated technologies are revolutionising many industries, boosting productivity, and driving economic growth.

According to a report released by PWC1, the integration of robotics is expected to catalyse the UK's Gross Domestic Product (GDP) as much as 10.3% by 2030. This shows the positive and significant impact that robotics will have on the country's economy in the near future, especially in light of recent domestic economic challenges. Contrary to common fears, the increased presence of robots in the workplace doesn't equate to job losses. Instead, the adoption of robotics will actually create more job opportunities and avenues for upskilling for existing employees.

The benefits of workplace robotics

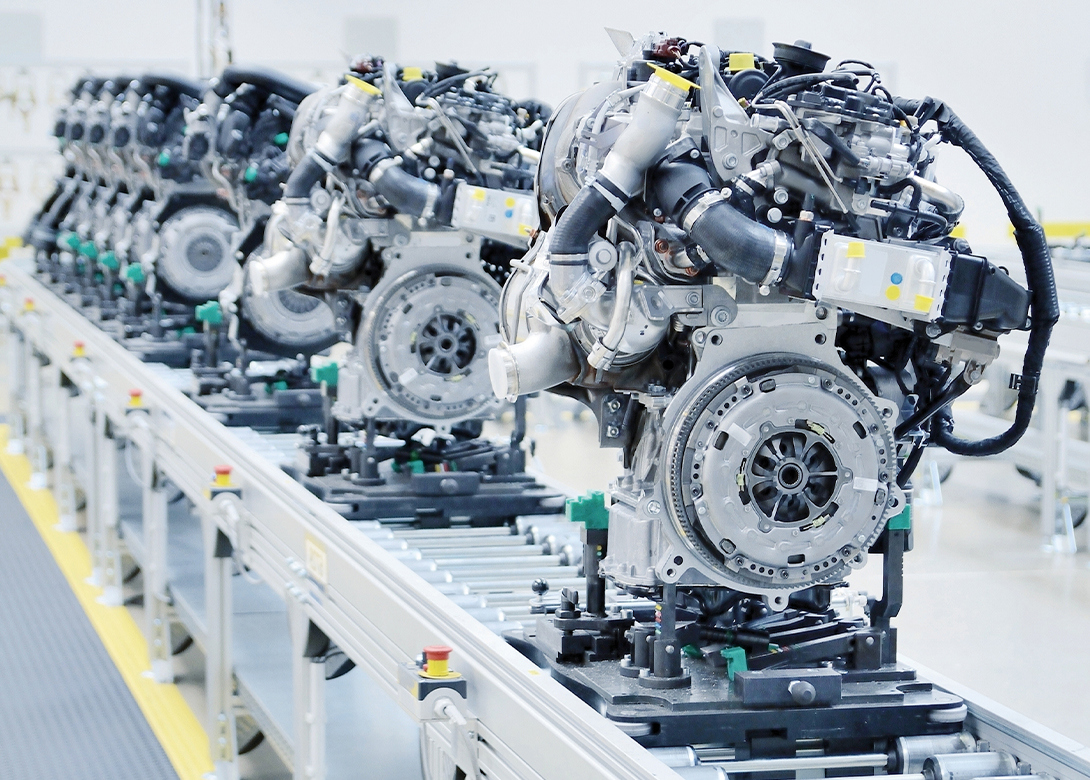

Robots are deployed across various industries and scenarios, taking over dangerous or repetitive tasks, such as those in manufacturing processes. By investing in production systems that handle predictable and repetitive tasks, spring manufacturers relocate experienced employees to focus on more complex responsibilities and critical decision-making areas.

Consequently, companies significantly enhance their efficiency and productivity, leading to successful business growth, all thanks to robotics. The cumulative effect of these advancements will undoubtedly contribute to the overall expansion and stability of the UK economy. While concerns may arise regarding the potential reduction of human workers in favour of robots, it's crucial to view automation as an opportunity.

Embracing robotics and AI will drive innovation, boost productivity, and promote job creation, according to the PWC report. Also, introducing robotics and AI could increase productivity by up to 14.3% by 2030. This particularly benefits small and medium-sized enterprises (SMEs), as this increased productivity creates greater demand for labour and opens up expansion opportunities.

Spring designs in robotics

Custom springs play a vital role in robotics designs due to their unique properties and functionality. They are widely used across various applications, including wearable robotics and larger industrial robot systems.

The designs of small springs in electronics2, such as robotics, offer many advantages. Notably, they can reduce axial space, enabling more compact designs in applications with limited space constraints. These micro springs deliver the necessary spring rate force while minimising the operating height compared to traditional coil springs.

In robotic systems, springs ensure mobility, versatility and adaptability, such as legged robots navigating through uneven workplace environments and unstructured terrains. The springs in robots let them navigate these diverse surfaces effortlessly. Different types of springs, such as compression, extension, wave, and elastomer springs, are used in robotics designs. During the design phase, machine design engineers consider factors like mechanical properties, geometry, and functionality to ensure optimal performance and reliability.

The role of wire forms in robotics

Reliable and high-quality wire forms are indispensable for ensuring robotics design functionality. These are typically crafted from high-grade materials like stainless steel, and as a result, these wire forms possess exceptional strength, durability, and precision.

Wire forms in robotics are used in almost limitless applications in various aspects of robotics, including actuation mechanisms, sensors, connectors, and positioning devices. However, precise design and manufacturing are crucial to maintaining tension, flexibility, and dimensional accuracy required for safe, predictable movements when the machine has been programmed.

This reliability and consistency are vital for robotic components' smooth and precise movement, guaranteeing efficient operation and reducing the risk of errors or malfunctions such as jammed parts. Proper sizing, dimension, and alignment are needed for appropriate installation and interaction with other mechanical components. Low-quality wire forms will compromise the overall strength and reliability of the robotics system, which is why UK manufacturers hold themselves to such high standards when creating products for these systems.

This reliability and consistency are vital for robotic components' smooth and precise movement, guaranteeing efficient operation and reducing the risk of errors or malfunctions such as jammed parts. Proper sizing, dimension, and alignment are needed for appropriate installation and interaction with other mechanical components. Low-quality wire forms will compromise the overall strength and reliability of the robotics system, which is why UK manufacturers hold themselves to such high standards when creating products for these systems.

The role of spring manufacturers for the future of robotics

When looking ahead at the rest of the decade and beyond, the influence of robotics on the manufacturing industry is projected to be profound, similar to the impact experienced with CNC machining's initial development. Automation, combined with robotics, is anticipated to enhance precision, speed, and flexibility within spring manufacturing processes, ultimately increasing productivity and cost-effectiveness.

Through the reliable outcomes of spring makers and the strategic integration of robotics in the workplace, the industry will benefit from heightened efficiency, expanded job opportunities, and sustained economic growth.

2 https://www.airedalesprings.co.uk/blog/springs-in-the-electronics-sector/

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.