HellermannTyton, manufacturer and supplier of cable management solutions, has recently joined forces with cable assembly manufacturers, Telecom Connections Ltd, to streamline its production lines and reduce manual operations.

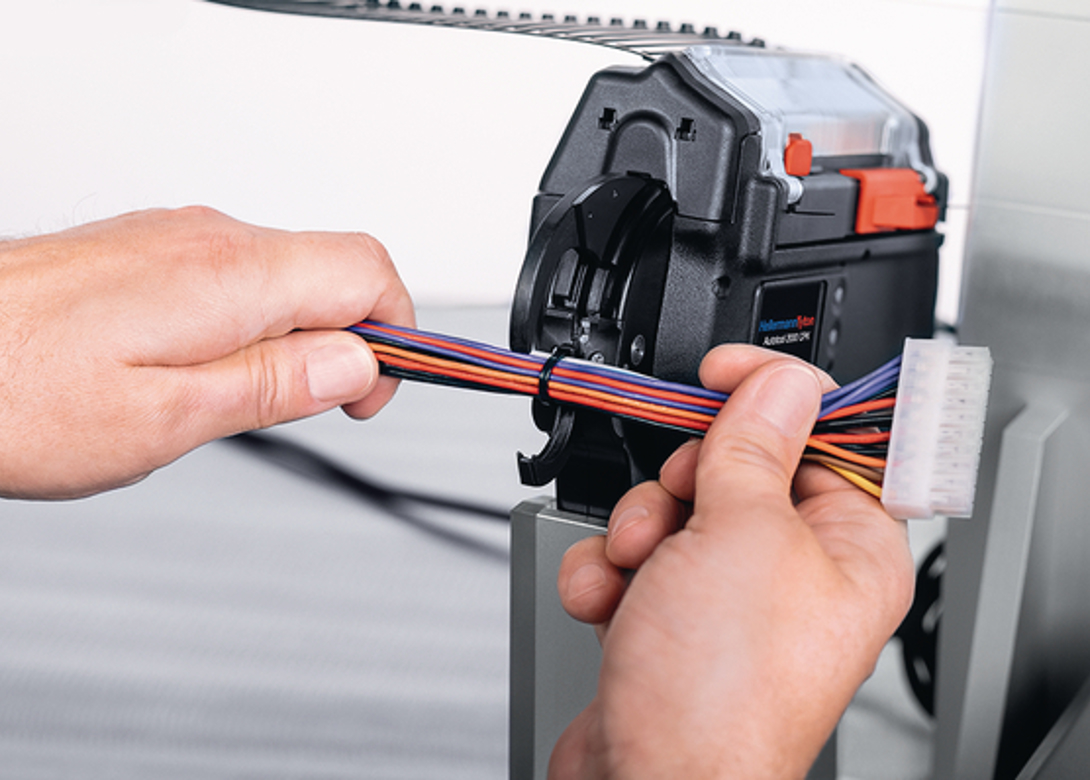

With the aim to reduce downtime and move away from manual methods of fitting cable ties to its cable assemblies, Telecom Connections approached HellermannTyton for a solution. Working closely with Telecom Connections to understand its requirements, HellermannTyton recommended its automatic cable binding solution to enhance production speed, quality and reliability.

Telecom Connections manufacture and supply a wide range of cable assemblies including surface mounts, wiring harnesses and looms to name a few. The business needed an automatic bundling system integrated into its production line to secure cables together quickly and efficiently, supplying customers with neat cable assemblies whilst reducing laborious production methods.

Telecom Connections uses over 50,000 cable ties each year when securing its bundled cables to reduce space and to allow sleeves to be applied over the cables. Looking for new ways to enhance the speed of production, improve quality and ensure reliability and repeatability, Telecom Connections worked closely with HellermannTyton to identify the best solution to reduce cable tie fitment time while retaining high-quality levels. The AT2000 now enables Telecom Connections to secure its cable ties using a semi-automated process, reducing fitment time by 75%.

John Brodie, product manager of fastenings and fixings at HellermannTyton explains: “Telecom Connections are a long-standing customer here at HellermannTyton, where we have built a strong and trusting relationship over the years. So, when Telecom Connections approached us for a solution, we worked together to find the best product for them. Reducing manual methods of cable tying was key to increase production capacity, resulting in the AT2000 Autotool being the best fit.”

The AT2000 is an electrically powered system for bundling electrical wires which can be used stationary or mobile using the Bench Mount Kit or the Overhead Suspension to relieve weight when holding it, depending on the customer’s application and requirements.

Customers can also integrate the AT2000 into a fully automated production line by using the Power Pack with integrated Control Box, which is the interface between the AT2000 and your production line. The cable ties used alongside the AT2000 system can operate in temperatures ranging from -40°C to +105°C, offering flexibility for customer applications.

Telecom Connections uses the AT2000 to secure cable bundles when manufacturing cable assemblies, ensuring the final product is compact and secure for customer applications.

“The AT2000 is a very intuitive and easy machine to operate, enabling us to move from a completely manual method to a semi-automated process. Manually fitting cable ties can be a laborious and time-consuming exercise using normal methods, and now thanks to HellermannTyton we’ve been able to semi-automate the process and cut down fitment time. The HellermannTyton brand is known for its quality within the industry, a quality we can now pass onto our customers,” commented Alex Goff, managing director at Telecom Connections Ltd.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.