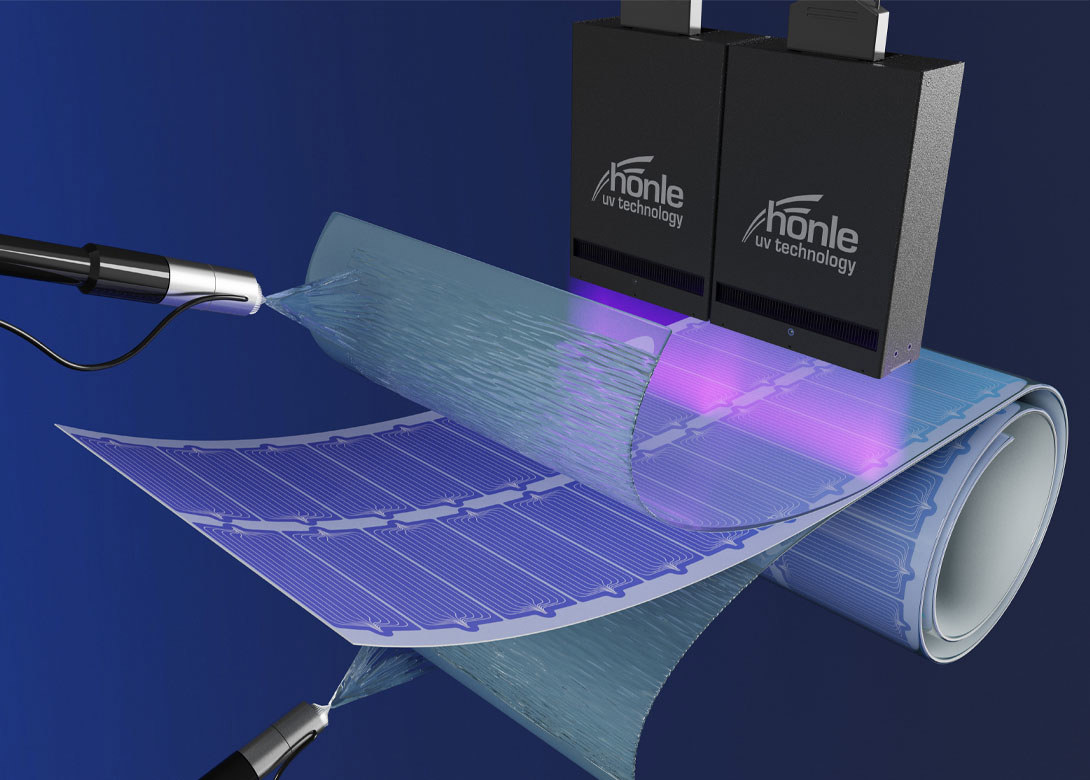

Radically new applications in consumer electronics are being created through the use of latest organic photovoltaics (OPV) and perovskite-based systems, including such uses as indoor light harvesting to extend the battery life of wearables, as well as outdoor energy generation, where performance and flexibility has previously been inconceivable using conventional photovoltaics. The same is true for flexible electronics, and a key enabler to both these advances has come from progress in bonding technologies. This is where Panacol’s developments in high-tech adhesives have helped advances in flexible photovoltaics to reach the next level.

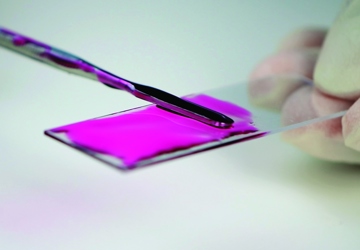

Today’s adhesives go beyond the provision of just the basic benefits of sound structural bonding, by providing additional functionality to an assembly. In this regard, German adhesive and coatings specialist, Panacol, has developed a range of multi-functional adhesive selections for applications in flexible photovoltaics and electronics. For OPV applications, for example, these adhesives provide higher resistance to environmental stresses, improved compatibility with PV materials, and good adhesive performance to various substrates. New conductive adhesives also adhere efficiently and protect electrical connections on surface mount device components in flexible assemblies.

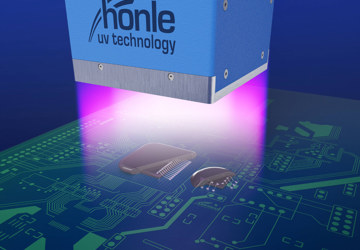

In all cases, the specific requirements of an application and its assembly process are key factors to consider when selecting an adhesive, because significant benefits can be realised when an optimal pairing is achieved between the component design and/or assembly, and the right adhesive properties, and curing process, e.g UV curing. High throughput processes, including roll-to-roll, can be run with greater efficiency as a result, which, in turn, reduces the total cost of operation. Adhesive requirements, such as flow properties, can actually be modified in this context to suit the application process, perfectly.

As new product designs are emerging rapidly, very little standardisation exists in the manufacturing of OPV, and in order to support this situation adhesives must be modified, or developed, to suit latest OPV designs, materials, and process requirements. For its part, Panacol, which has been supplying adhesives, coatings, and UV/LED curing equipment for OEMs and contract electronics manufacturers around the world for more than 40 years, has anticipated this changing need and expects to offer such customers rapid adhesive customisation and development, to meet their latest requirements.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.