The UK Technical Assessment (UKTA) certification has been secured by Aptus, a specialist supplier of fixings and fastenings to the construction industry, for its pro-struct® structural timber screws.

Aptus’ approval follows in-depth assessment conducted by the British Board of Agreement and certifies the entire pro-struct® range as complying with the requirements set out for screws by European Assessment Document (EAD) 130118-01-060, parameters which assess a product’s performance against 14 different criteria.

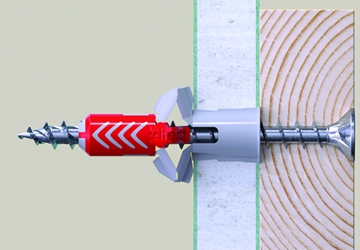

To ensure they can offer a working life of 50 years when used in applications, such as forming connections, or securing insulation to rafters, the pro-struct® screws employ a number of innovative features. Specifically, they are manufactured from a specialised grade of steel, which is combined with an advanced heat treatment process that enables them to accommodate the natural movements of timber without shearing. They also benefit from cutting-edge thread geometry for a quicker drive and better pull-out resistance, as well as a larger diameter head, which improves resistance to head pull-through. Their zinc plated coating, which has been salt spray tested to 500 hours, also ensures compliance with service Class 2 of Eurocode 5.

Like all Aptus products, the pro-struct® screws are backed by UK-based technical support and have been developed specifically for the UK market, with gauges available including 6mm. This gauge is more suited to the narrower joist sizes employed in the UK compared to 8mm diameter screws typically designed for the larger joists used in Europe. Aptus’ pro-struct® structural timber screws are currently available in a variety of lengths up to 300mm, with a 400mm option expected to be launched soon.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.