A six storey building and 500 apartments are being built as part of a comprehensive building complex on the river Mersey in Liverpool, in Miller’s Quay. The construction is part of the Wirral Waters project, one of the UK’s largest and most sustainable regeneration projects. fischer BWM substructure solutions secure the rear-ventilated rainscreen façade clad with metal on a surface of 12,000m².

The implementation of the million-pound construction project began in 2022 and is set to be completed by early 2025. As the façade construction company responsible for the project, the FK Group (UK) used a fischer BWM substructure solution to install the rear-ventilated rainscreen façade, in addition to the ATK 100 minor aluminium supporting structure. Cap profiles were horizontally attached to the vertical carrier profiles, onto which the visible fastenings of the corrugated iron cladding were installed.

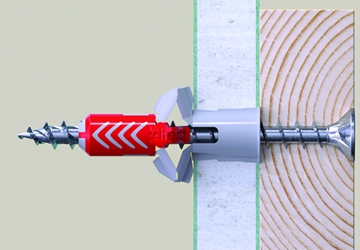

Wall holders securely and firmly anchor the overall setup in the load-bearing substrate. fischer FAZ II bolt anchors made of stainless steel were used to fasten the holders to the reinforced concrete. In order to attach the wall holders in the masonry also contained in the anchor substrate, the façade construction specialists opted for the fischer FIS V Plus injection mortar together with the corresponding system components as well as fischer Thermostops. These elements thermally separate the wall holder from the construction base, thereby reducing thermal bridges. Vertically and horizontally installed fischer FireStop fire barriers provide added structural fire protection.

“We won over the façade construction specialists at the FK Group with the right substructure solution for the project as well as with our accompanying services,” emphasises Mertcan Güler, sales manager façade at fischer BWM Great Britain. “Our company provided the best possible technical support as far as six months before implementation. This included static and thermal calculations for the facade fastening, which we created separately for the various individual parts of the project.”

fischer also supported its client by providing additional DWG drawings and strength calculations. “Our services ranged from planning and construction site visits, pull-out tests, expert advice and on-site support to custom profile cuts,” Mertcan adds.

Stefan Schrag, market manager at fischer BWM, stresses: “We will provide support to the façade construction specialists until the project’s successful completion and will continue to be there for them at all times after that.”

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.