Importer and distributor of high-quality hardwood decking, siding and industrial products, Nova USA Wood, has been working with ARaymond, a global provider of fastening and assembly solutions, to create a more cost-effective patent sliding clip, used to fasten wood panels to residential and commercial structures.

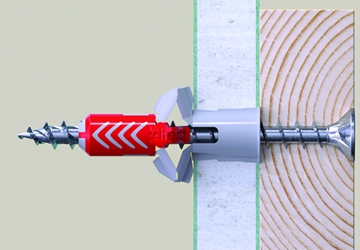

Nova originally designed its own patented Rainscreen Clip system, known as ExoClad QuickClip for quick and efficient installation of rainscreen siding. “What’s critical here is that the fastening component offers an air gap between the siding material and the structure itself. Designing anything with wood means that you must account for the potential swelling or shrinkage in your design, especially when you expect that humidity levels will not be consistent over time,” explains Nova co-founder, Steve Getsiv. “As is the case with exterior siding, the wood swells when exposed to high humidity levels - such as on a rainy or foggy day. Conversely, the wood will shrink during dry spring or summer weather.”

Nova’s ExoClad QuickClip provides this gap, allowing for the expansion and contraction of the wood while maintaining a secure attachment. However, the clip was originally made from extruded aluminium, which must be sourced externally and is costly. “Aluminium extrusion requires aluminium mixers and a lot of processing, which adds to the costs. The material is extruded, then cut to size, and finally requires holes to be drilled for the screws. It’s a bit of a complicated process.”

For these reasons, the founders of Nova had considered switching to composites, which require no post-processing as the component is manufactured as one part. The conversation with the engineers at ARaymond led to further investigation.

The primary challenge in swapping aluminium for composite for Nova’s Rainscreen Clip was that the overall shape, size, and structure of the component could not change. Essentially, there was zero flexibility in the design.

“From an engineering standpoint, we were limited on how much we could change in terms of the product packaging. So, we really had to get creative with our design because of the product constrains,” explains Jason Reznar, senior development engineer at ARaymond. “It was necessary to maintain the same footprint and configuration of the clip. For instance, we had to ensure the space between its wings so it not only fits into the grooves of a wood panel but also maintains the required gap without failing.”

This meant ARaymond was limited in relation to strengthening the composite used to match the requirements of the aluminium. “It was really a matter grade. What grade of composite would reliably meet the product requirements without modifying the clip’s structure,” says Reznar. “We started with a low grade composite just to get an idea of where we needed to go. Eventually, it became clear that we had to strengthen the material with an additive to reliably meet the load and force requirements - and we did.”

From the initial conversation with Nova, ARaymond was able to work through design simulations, composite grades, cycle testing, and print a 3D prototype for fit and function, completing the final product in just under a year.

“We were also able to brand the composite with Nova’s logo, which is something that was not possible when they were buying aluminium from an outside source,” says Wiggin. “It’s an added touch that’s special for Nova, ensuring their name is associated with each ExoClad QuickClip.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.