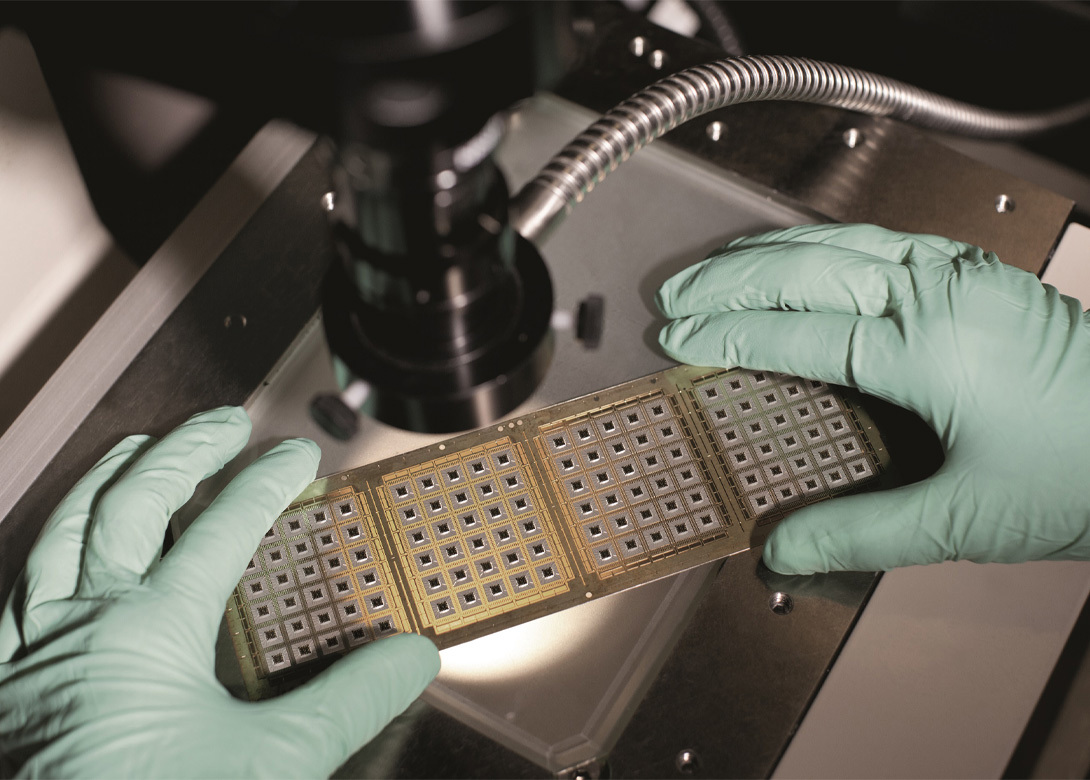

Recently, Henkel has announced the release of a die attach adhesive that provides high thermal capability to enable operation of power semiconductor packages. With 30 W/m-K thermal conductivity, Loctite Ablestik 6395T is the latest in the company’s portfolio of high thermal solutions and allows integration of back-side metallised or bare silicon die.

Elevated operational temperature is a key factor influencing die performance, so thorough heat dissipation helps ensure functional execution and long-term reliability. Henkel’s global market segment head for semiconductor packaging materials, Ramachandran Trichur, explains the mechanism of heat transfer from the die and why material selection is critical:

“For most high-power semiconductor packages, the primary path for heat dissipation from the device is through the die attach material. Because the material is in direct contact with the die, its thermal characteristics – which include material thickness, thermal conductivity, and thermal resistance – are the most important. Loctite Ablestik 6395T’s 30 W/m-K bulk thermal conductivity provides excellent heat transfer for metallised or bare silicone die.”

Most high-power semiconductor applications, like those found in electric vehicles, industrial automation systems, and 5G infrastructure components, also demand good electrical conductivity. Too much electrical resistance between the die and the package can result in energy loss and reduce the device’s energy efficiency. As in the case of thermal capabilities, package electrical performance is largely influenced by the die attach layer – especially in power ICs, where die attach is the most significant contributor to electrical resistance. Loctite Ablestik 6395T improves energy efficiency by lowering resistance.

Additionally, Loctite Ablestik 6395T exhibits low VOC content upon curing. The adhesive also meets automotive grade 0 thermal cycling and MSL 1 reliability standards on die sizes up to 3.0mm. Henkel also states there is no resin bleed out when using Ablestik 6395T.

“While electrical and thermal capability are top priorities, a streamlined bill of materials is also important for customers. Loctite Ablestik 6395T allows metallised or non-metallised die integration, delivers lead frame flexibility, and allows for a wide die size range – all using a high-reliability formulation. Henkel has achieved this unique balance of supply simplification, processability, and thermal and electrical performance, effectively extending the company’s leadership in the high thermal die attach space,” concludes Trichur.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.