Technical calculations of springs is one of the most important tasks for the Lesjöfors Group's technicians and sales staff. With an advanced calculation program most calculations can easily be performed with the highest accuracy.

Sometimes the purpose of a calculation is only to check that the dimensions on the drawing matches the specified load requirements, but equally common is that the calculation is made to select the appropriate material and spring dimensions to meet the requirements of spring forces or spring torsion. In the latter case a proposed technical solution is presented for the customer, usually in the form of a data sheet from a calculation program.

"The advantages of a customised program are many, but the most important of using our self developed software OptiSpring is the ability to update calculation models and material databases based on our continuous testing and development work. In this way, we can use the latest knowledge in our daily technical cooperation with our customers," explains Stefan Musslinder, technical manager at the Lesjöfors Group.

Fast advanced calculations

Another important advantage of a special designed program is that the user interface is adapted to the needs of the company. OptiSpring allows Lesjöfors' technicians to make a control calculation of a single spring geometry in just a few seconds, while the same program can be used for much more complex design work.

Most spring types are included

OptiSpring includes modules for most of the spring types that Lesjöfors manufactures: compression springs (linear, conical, cylindrical progressive and nested springs with linear compression springs), tension and torsion springs, disc springs, wave springs and flat spiral springs (power springs and clock springs). For wire and strip components with complex geometry and/or highly non-linear characteristics, the finite element program Ansys is most often used.

Detailed description in data sheet

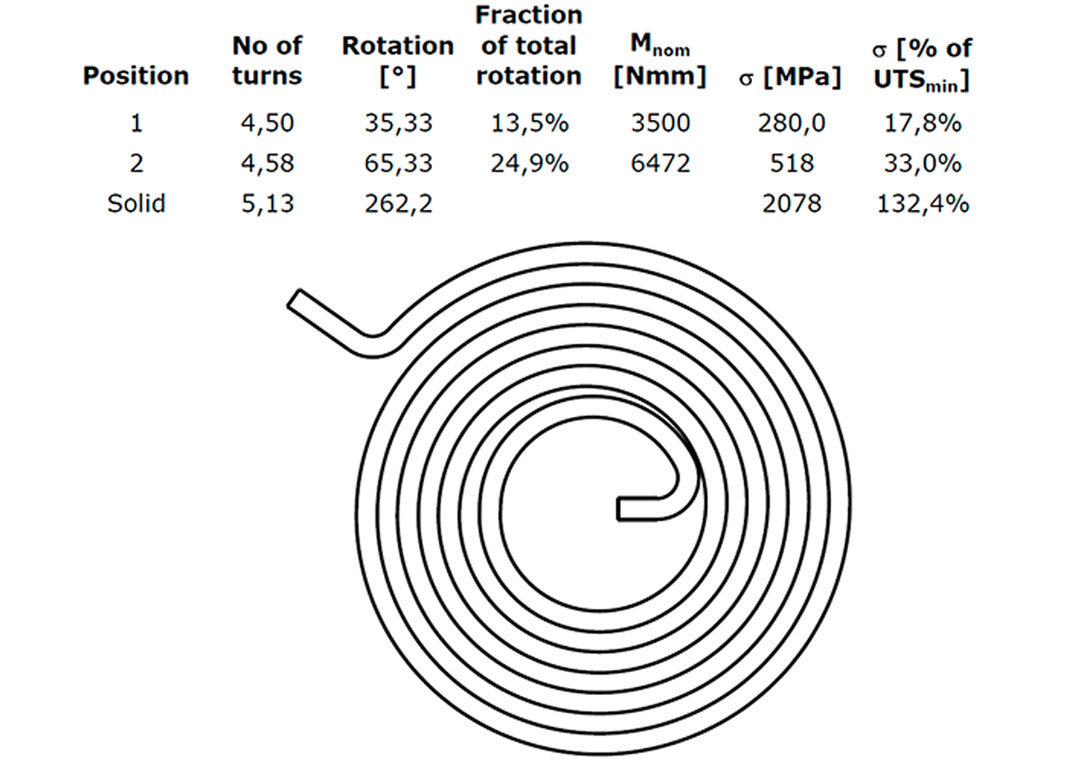

The detailed data sheet is for all spring types divided into four sections. The first section describes the characteristics of the material and the second contains spring dimensions including tolerances. The sections "load data" and "stress analysis" describe the spring under load in its application." Forces or moments should ensure proper function, while the stresses in the spring is what we use to assess whether the spring will fulfill lifetime demands, especially regarding relaxation and/or a requirement for fatigue lifetime, i.e. the number of load changes between the two positions," says Stefan Musslinder.

Spring details as manufacturing specification

In addition to these four sections, some extra information is available depending on the spring type. Goodman Fatigue Chart is available for linear compression springs, while a principal sketch of the spring is presented for other spring types.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.