Seeking to optimise faster manufacturing, LISI Aerospace is introducing Markforged Composite 3D printers to optimise faster manufacturing of high-quality fasteners for the aerospace industry, whilst maintaining stringent standards and produce at a lower cost across multiple variants.

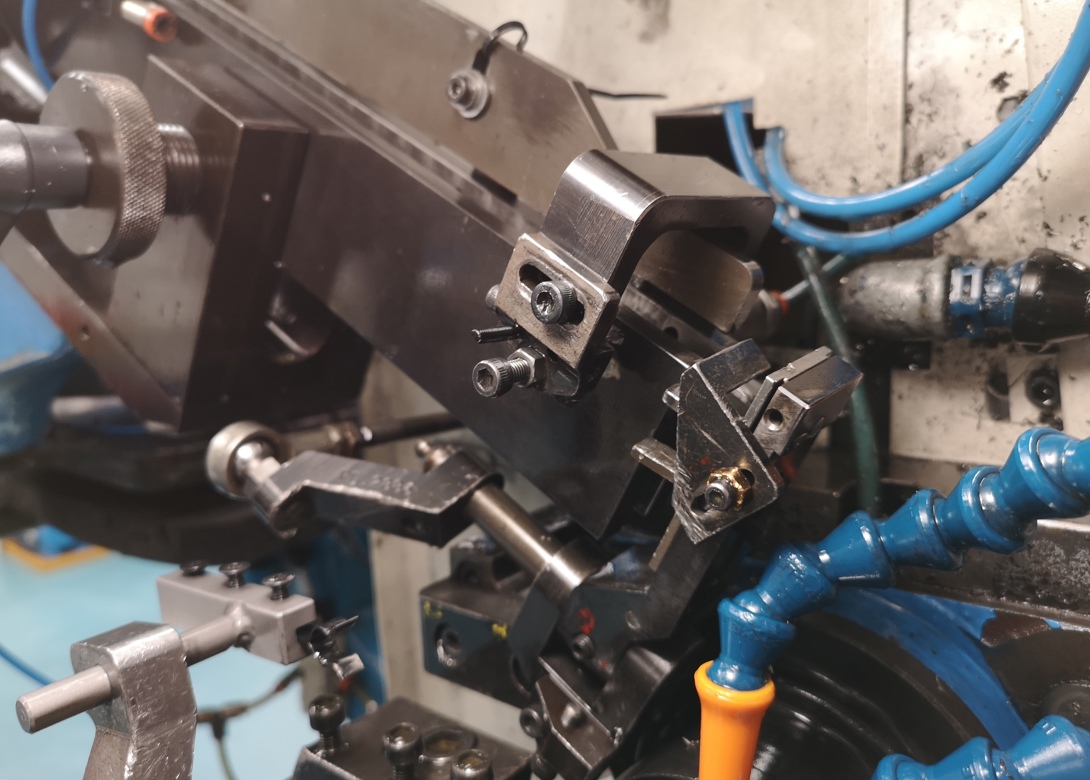

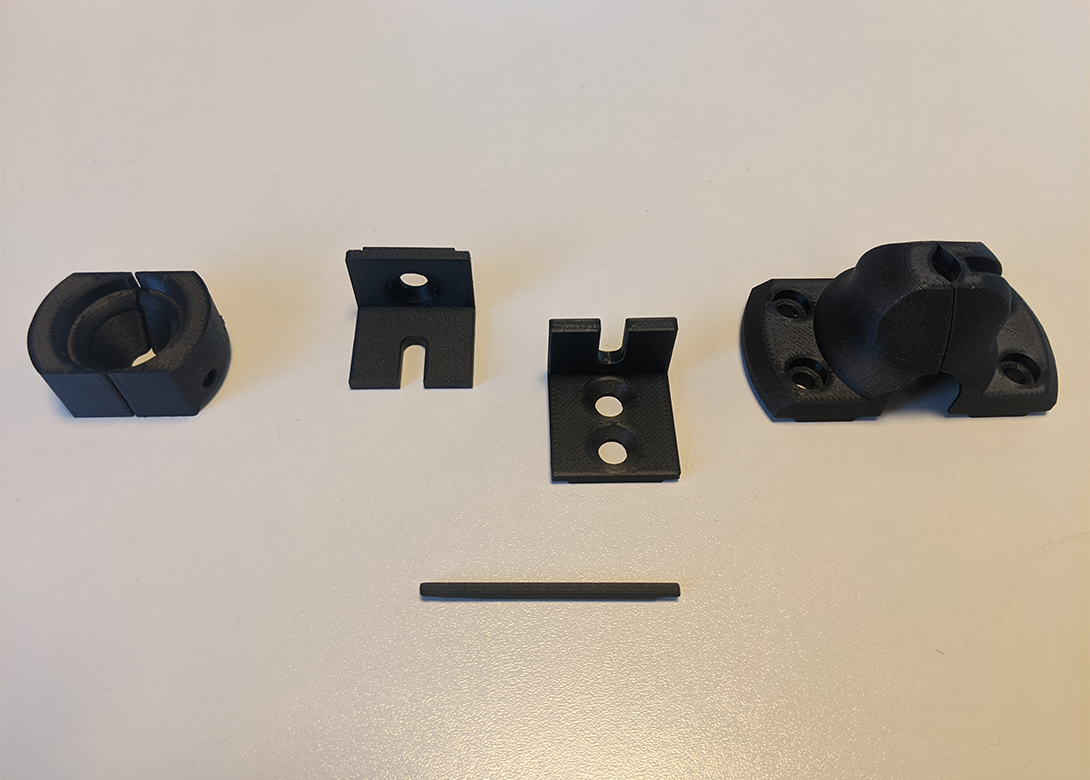

Working together with UK-based additive manufacturing solutions provider CREAT3D to meet the requirements of the three key issues of high volume of variants, safety and timely delivery, LISI Aerospace has embedded Markforged 3D printers within its manufacturing department at its UK plant in Rugby, to produce bespoke and replacement tooling and components for the production lines, as well as functional prototypes for design development and testing.

This UK manufacturing plant specialises in the manufacture of fasteners for the aircraft industry, providing fasteners for key clients including Airbus and the Civil Aircraft market. Key criteria for the manufacturing team are performance excellence, safety and innovation. The manufacturing unit produces numerous variants of fasteners every day, split into 3 core departments: feeder (raw materials), manufacturing, plating testing and dispatch.

Typically, between 95% - 98% of these fasteners are produced in Titanium, however, a small percentage of parts are made in steel. Producing a range of fasteners, LISI AEROSPACE has a huge challenge, with a high number of variants within each product category – which can be a challenge.

To reduce the number of change overs required, the production lines are set by the diameter of the fastener. However, there are a huge number of variants of products and in addition bespoke and fast-track batches are often ordered by clients at short notice, requiring agility and fast problem solving.

Due to the nature of the aerospace industry, the manufacturing unit also operates to very tight tolerances and stringent testing, so any processes must meet these standards. Time is also of the essence, with on time delivery very important. As a tier 1 supplier to aerospace and Civil Aircraft markets, LISI must be able to deliver on production schedules to ensure manufacturing at their clients’ sites is not impacted. Keeping the production lines running effectively is essential.

Having worked with LISI for over 5 years, CREAT3D have helped to shape LISI’s Additive Manufacturing capabilities through applications engineering, training and advice, tailoring their Additive solution across multiple departments, resulting in immediate savings and cross-functional team benefits. Having started with Ultimaker FFF printers, in 2020 the teams in manufacturing and plating enhanced their additive capabilities with the addition of multiple Markforged Composite 3D printers.

This has resulted in fast problem solving and higher productivity, with less damage, wastage and downtime; the ability to identify and fix issues earlier on in the production process; as well as improved preventative maintenance for reduced stoppages.

“We will never go back to operations without Additive. We are just going to use it more and more, identifying more parts and applications that can be 3D printed. Tooling is a key area which will just keep expanding,” enthuses LISI. “Where can we use our 3D printers where we are not currently using them?”

Additive manufacturing is valued not only on the shop floor, benefiting daily tasks and performance, but also at a strategic level by middle and senior management due to the cost and time savings, with more agility and higher productivity.

LISI’s future with Additive highlights the company’s approach to being the very best through constant innovation. With further Additive applications expanding through continuous improvement, and the awareness and benefits of using the technology growing within LISI, Additive technologies will continue to be used by the teams as the go-to for solving engineering problems.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.