Henkel has developed a range of universal structural bonders using new patented hybrid technology. This innovative approach substantially extends the application scope of these adhesives - combining the qualities of different adhesives helps to achieve bond strength, speed and durability while providing improved performance on a variety of substrates.

Structural bonding has been a tremendous force for change in the way products are designed and made. It allows materials to be selected for their respective performance qualities rather than their compatibility with the joining method; plastics, metals and composites can be freely combined.

The adhesive also creates uniform distribution over the entire bond face achieving a very positive effect on static and dynamic stress, contributing to the durability and reliability of the end product. The join is relatively invisible so the aesthetics of the product are enhanced.

The new LOCTITE® HY 4090 provides a good example of the potential of the range to improve assembly applications, streamline process steps and bond materials in applications with difficult requirements. It provides exceptional adhesion and strength on plastic/metal combinations and on rubber materials. Fast fixing reduces assembly time and a robust cure is quickly achieved even at low temperature, as well as when there is a relatively large gap between substrates.

Henkel states the universal structural bonder offers good impact, vibration, moisture and temperature resistance and is able to withstand chemical attack making it suitable for production lines that include a chemical process.

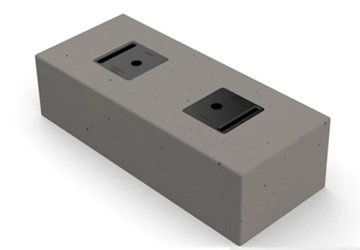

LOCTITE HY 4090 can be used for general assembly applications involving mixed substrates – especially moulded plastic/rubber or poorly fitting parts – in a high volume, semi-automated or manual assembly line. Typical applications would be wire harness and gasket bonding, sealing and bonding LED lighting fixtures, motors and loudspeakers. The product is available in easy-to-use 50ml syringes and 400ml cartridges.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.