By Jeremy Scholefield, director of strategic business, TR Fastenings Ltd

For over 25 years, TR Fastenings has been working with leading healthcare organisations and their subcontractors as a total solution provider of fasteners and ‘Cat C’ products. TR has therefore geared up its capacity to support the medical technology industry during this critical time.

The current landscape

The outbreak of Covid-19 created an unprecedented demand for medical products, a situation never before experienced on this scale at any time in living memory. In response to the outbreak, the world turned to medical companies for vital help, which has galvanised the industry into action and to work in uncharted territories.

To meet the urgent global demand and to alleviate shortages, many manufacturers from outside of healthcare are now reconfiguring their business to develop and produce medical equipment and supplies.

It has been a high growth market for many years and according to the Evaluate MedTech Report produced in 2018, the global medical technology industry is expected to grow at 5.6% per year to reach worldwide sales of US$595 billion by 20241.

As the pandemic unfolded, the governments and public health services of England, Scotland, Wales and Northern Ireland established several NHS Covid-19 critical care field hospitals in various locations across the UK. These temporary hospitals, named NHS Nightingale after nursing pioneer Florence Nightingale, were set up to cope with the anticipated overflow from existing hospitals. We have also seen similar actions being replicated globally.

Medical devices are playing a crucial role in the fight against Covid-19. The critical products requiring fasteners and components are:

- Respiratory support and monitoring equipment such as ventilators, which help to treat hospitalised patients.

- Personal Protective Equipment (PPE) such as face masks and protective visors.

- Diagnostic tests that identify those infected and further limit the spread of the virus.

TR Fastenings responded to the UK Government’s urgent request to support the immediate needs of established medical equipment manufacturers and new companies diversifying into this sector. With technical expertise, real time inventory availability, a wide range of fasteners, and an intricate global supply chain already in place, TR has been able to accelerate time to market.

The role fasteners play in medical devices

Although fasteners are typically the smallest components in medical devices, they play an important role in the assembly, functionality and structural integrity of the device. Working directly with a knowledgeable fastener manufacturer early on in the design stage mitigates the possibility of a costly redesign after the product has been launched.

The challenges of working in a changing world

TR’s fast-track approach to delivering a high volume of products, often within hours, supported the sudden acceleration of customers’ needs. TR worked through weekends and bank holidays to respond quickly and engage with various medical companies around the world.

The main products TR supplies are sheet metal fasteners, high grade stainless steel fastenings, plastic and rubber products, plus specially manufactured parts to be used in a range of medical equipment. This includes ventilators, medical beds and furniture, ultrasound machines, medical imaging equipment, defibrillators, incubators, medical computer stands, volumetric pumps and infusion devices, vacuum extractors and many other vital pieces of medical equipment.

New medical hardware products introduced

TR has introduced two new products to its range – the L-bow Handle and a Face Visor Kit. The L-bow Handle can be retrofitted to an existing compatible door handle and allows the door to be opened ‘hands free’ with a forearm, reducing the risk of direct contact with viruses and bacteria on the door handle. The door opener is made from plastic with stainless steel components and works on various door types with both horizontal and vertical handles from 19mm up to 22mm diameter. Available from stock in black and to order in any other RAL colour (minimum 1,000 pieces).

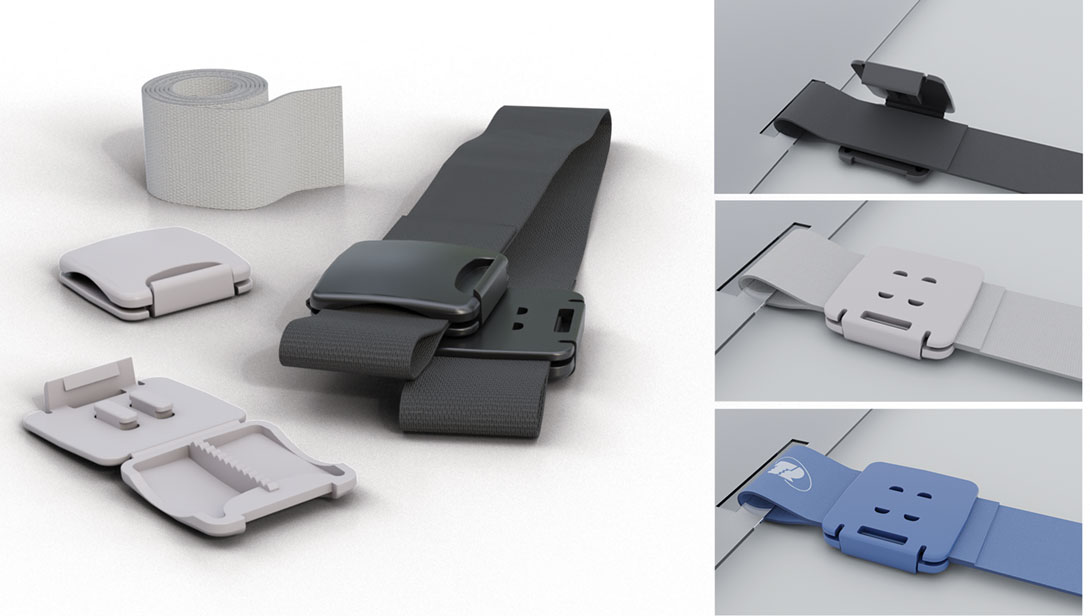

The Face Visor Kit contains two polypropylene clips and a 330mm elastic strap – making it quick and easy to fit. A secure, lockable and adjustable method of attaching a strap to a face visor. The kit can be manufactured in various colours. Simple finger pressure closure and release mechanism. The standard 19mm elastic strap can also be provided in a 15mm width, and 1mm increments up to 19mm.

Application engineering has proved to be key

In addition to choosing a high-quality fastener manufacturer and distributor with a diverse product range, it is also important to work with a company that offers application engineering expertise. TR engineers are fully engaged in the design and make critical recommendations for the interface between the fastener and the medical device.

Due to Covid-19 lockdown restraints, TR engineers have fully utilised the ‘modern workplace’ by using various methods of online virtual communication to ensure the customer receives the highest level of service and technical support.

The future

As the medical landscape changes, preparing for the future has never been so important. TR Fastenings is ready to meet the challenge.

1 Market size extrapolated from EvaluateMedTech Report,World Preview 2018, Outlook to 2024 https://www.evaluate.com/thought-leadership/medtech/evaluatemedtech-world-preview-2018-outlook-2024

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.