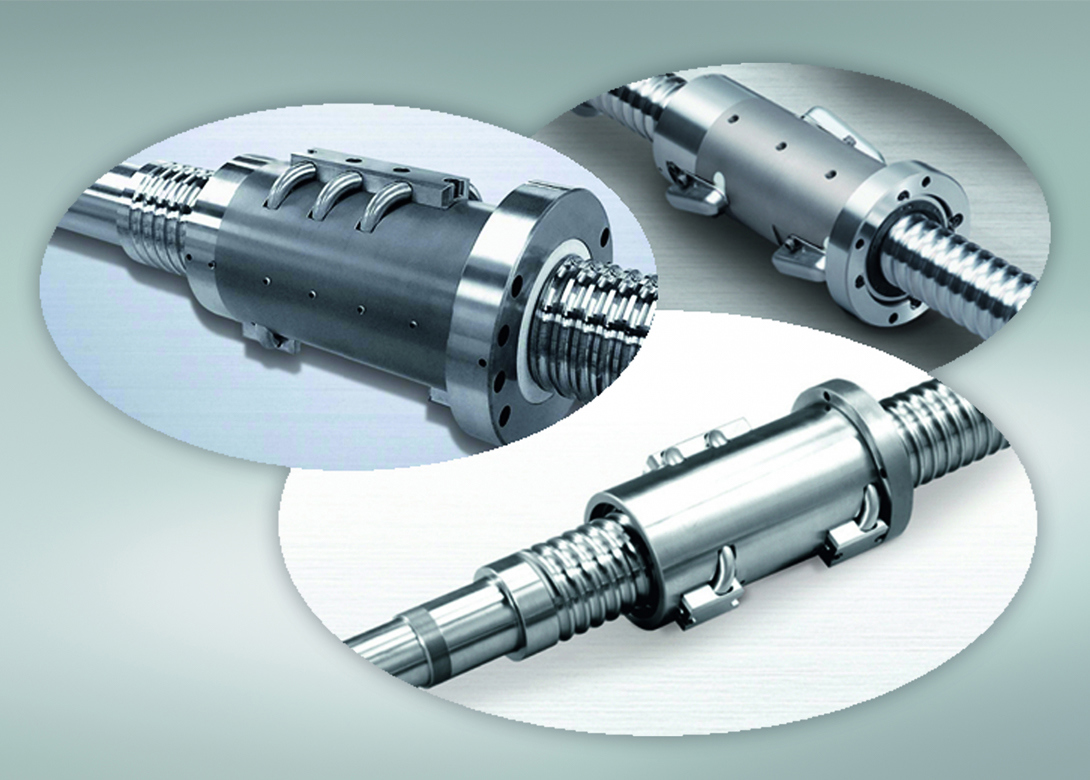

NSK has developed new technology that extends ball screw life in high-load applications, such as injection moulding machines and servo presses.

NSK Ltd insists its latest long-life ball screws offer up to twice the service life of conventional ball screws due to the optimisation of load distribution. Resource conservation through extended life and the downsizing of machinery is a further advantage.

By developing special long-life technology that balances load distribution more evenly, NSK extended the life of its ball screws up to twice that of conventional designs. The new technology came about through a combination of NSK's high-precision machining capabilities, the company’s digital-twin simulation technology and its precision measurement systems.

With sustainable development goals and carbon neutrality initiatives advancing in many countries, there is a need to enhance the environmental friendliness and functionality of industrial machinery. Here, manufacturers of injection moulding machines and servo presses, for example, are switching from hydraulic to electric drive systems using servo motors and ball screws to save energy. As a result, OEMs are looking towards ‘high-cycle’ designs offering short processing times. Quicker, more frequent operation in turn demands the use of long-life ball screws. The dimensions are completely interchangeable with NSK's current equivalent models, so no machine design changes are necessary.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.