In 2017, the Fraunhofer-Gesellschaft launched the lighthouse project ‘futureAM – Next Generation Additive Manufacturing’, with the goal to accelerate the additive production of metal components. The project has now ended and six Fraunhofer institutes have made technological leaps in systems engineering, materials and process control as well as end-to-end digitalisation, thus increasing the performance and cost-effectiveness of metal-based additive manufacturing along the entire process chain.

On the one hand, the futureAM partners have focused on integrating the digital and physical value chain from incoming orders to the finished metallic 3D printed component and, on the other, on making a leap forward into a new technology generation of additive manufacturing. The digital platform Virtual Lab plays an important role in this, as it pools competencies digitally and makes the entire AM process transparent for all partners involved.

“We are now on the threshold of industrial implementation,” says Christian Tenbrock, group leader at the Fraunhofer Institute for Laser Technology ILT and futureAM project manager. “The expertise we have gained together is now to be transferred to industrial application.”

A major challenge for futureAM was the interplay between all participants, some of whom cover very different areas of the entire process chain. The Virtual Lab, a digital platform that ensures the exchange of information across all AM task areas and players, has proven its worth. In this context, the Fraunhofer Institute for Additive Production Technologies IAPT has developed various software tools for the design of AM components. In this way, it has created web-based simulation tools for metal AM, tools that can also be used by beginners.

In the “Materials” field of activity, the Fraunhofer Institute for Material and Beam Technology IWS, Dresden, has researched which materials can be combined with each other in a component and which problems arise in the process. Among other things, the Dresden researchers have dealt with expanding the applicable spectrum of additively processable high temperature materials and researched how these can be analysis, the institute could analyse a wide range of influencing factors and optimize the manufacturing process. Fraunhofer IWS demonstrates how well the process already works using multi-material components made of nickel and aluminium. Depending on the component requirements, the researchers add either a third or fourth element in order to adapt the properties exactly to the respective application.

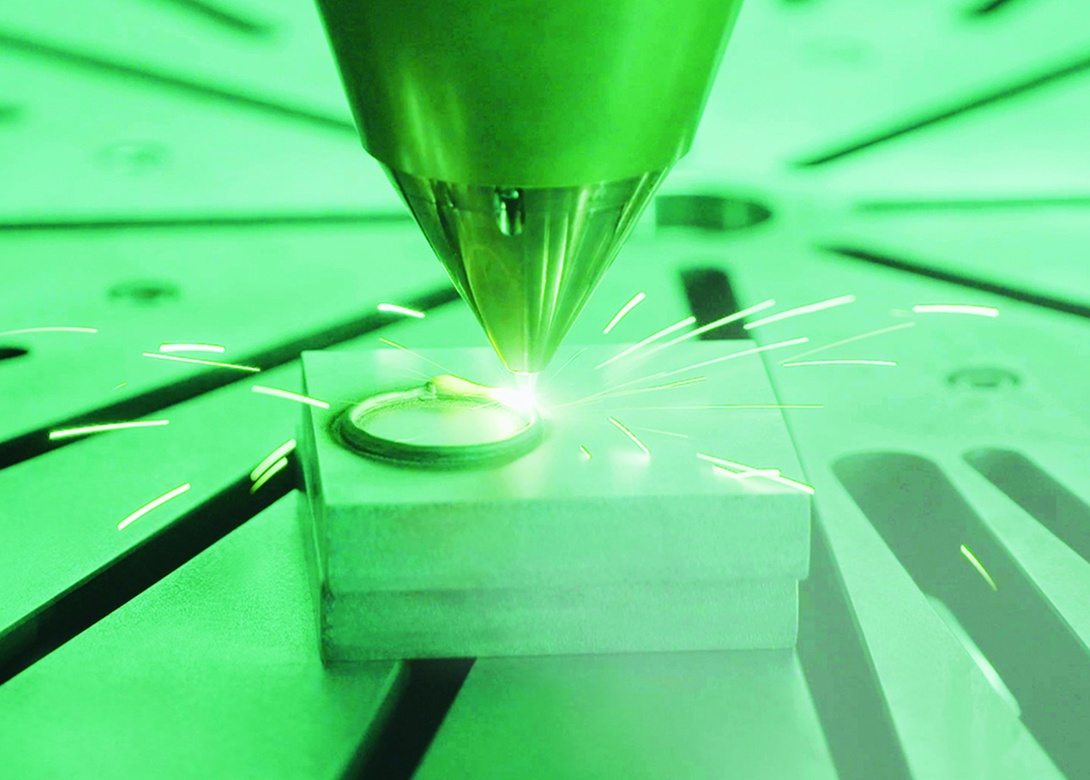

The scientists at Fraunhofer ILT in Aachen have developed a demonstrator system built by a machine manufacturer. It is a system for 3D printing of components on an XXL scale. For example, a demonstrator component for future generations of Rolls-Royce engines could be manufactured with laser powder bed fusion (LPBF) thanks to the large build volume (1,000mm x 80 mm x 400mm) and a new machine system with a mobile optical system. Similar successes have been achieved with extreme high speed laser material deposition (EHLA), which can now also be used to produce 3D components. The newly developed process allows extremely quick deposition speeds with high detail resolution.

The researchers also identified great potential for optimisation in post processing. The Fraunhofer Institute for Machine Tools and Forming Technology IWU in Chemnitz, therefore, developed an automated solution for this as part of the project. To enable the process to identify and track the physical component beyond doubt and continuously, a code is incorporated during manufacturing and read out later. This code also ensures efficient and trouble-free copy protection. In the next step, the actual geometry of the clamped component is recorded by laser scanners and the optimum processing strategy derived by comparing the target and actual geometry. The processing is then automatically carried out by a robot and is verified in the process by renewed 3D scans.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.