Recently, a survey was completed in the US which indicated that 23% of all service problems were traced to loose fasteners. In this article extract, Dr Bill Eccles from Bolt Science outlines the fastening problems that can be caused by loose fasteners.

The drive for improved quality throughout the manufacturing industry has impacted the assessment for accurately measuring assembly line torques. The critical weakness in many products is the region of joints which exist in the design. Bolted joints, particularly, can be a source of concern for the engineer. A single bolt, inaccurately or incorrectly tightened, can lead to the failure of the product. Too high a tightening torque and there is risk of a bolt shank or thread stripping failure. Too low a specified torque and the bolt tension can be inadequate to meet functional requirements. Such failures could occur either during production assembly or during subsequent maintenance on the product after it had entered service.

The most prevalent controlled method of tightening threaded fasteners is to ensure a specified torque is achieved, a method known as torque control. The major problem related to this method is the clamp force generated by the applied torque is dependent upon the design of the fastener and the prevailing frictional conditions.

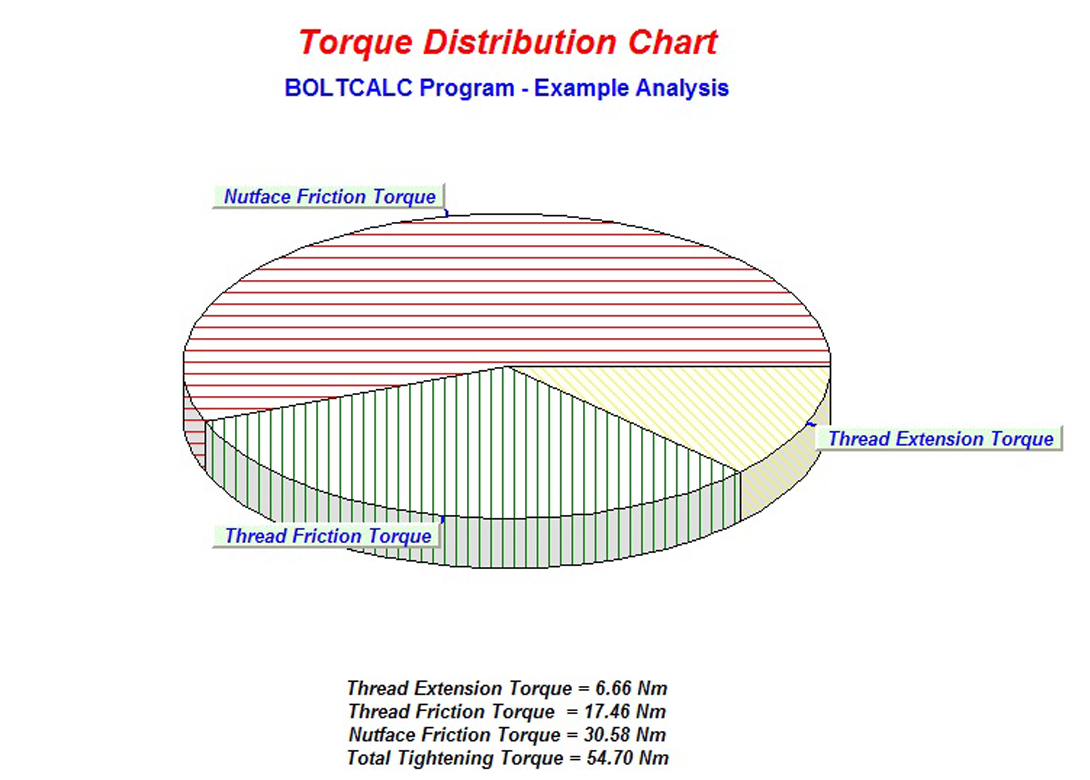

The problem with using the torque control method to indirectly control the clamp force in the fastener is that only a small proportion of the torque is used to extend the bolt. The majority is absorbed by friction between the nut face, in the joint and in the threads. Some fasteners use a nylon insert or have a distorted thread, so a torque is required to run the nut down an unclamped bolt thread.

Interestingly, for the same stress in the bolt, the required tightening torque between the prevailing and non-prevailing bolt types varies by less than 4%. But the prevailing torque type nut results in significantly less preload (16%). An example of the distribution of torque within the fastener for a M10 Property Class 10.9 bolt is shown in the pie chart, sourced from Bolt Science’s BOLTCALC program.

To read the full article, as well as get Bill Eccle’s techniques for ensuring threaded fasteners are tightened correctly so the desired preload is achieved:

click herewww.boltscience.com

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.