A necessary but time-consuming task performed by wind turbine technicians is to check for any loss of tension in the thousands of bolts holding the structures together - each bolt must be retensioned individually. Now, with Bolt-Check developed by Danish wind turbine tools expert, R&D A.S, the bolt tension can be checked much faster, with higher accuracy and full traceability.

R&D says this results in a time saving of up to 50%, as well as technicians benefitting ergonomically thanks to the reduction in the repetitive actions involved when continually handling heavy tightening tools during maintenance.

In wind turbines the bolted joints need to withstand higher centrifugal and bending forces, as well as stresses and vibrations. Incorrect bolt tension in wind turbines is a common complication that can both result in expensive call-out charges and downtime which, at worst, can result in the failure of the entire turbine. Checking the condition of the bolts to ensure safe and reliable performance is therefore an important maintenance task.

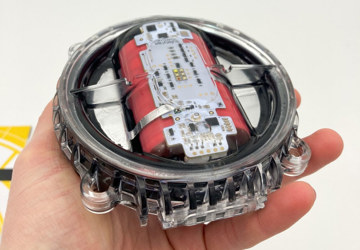

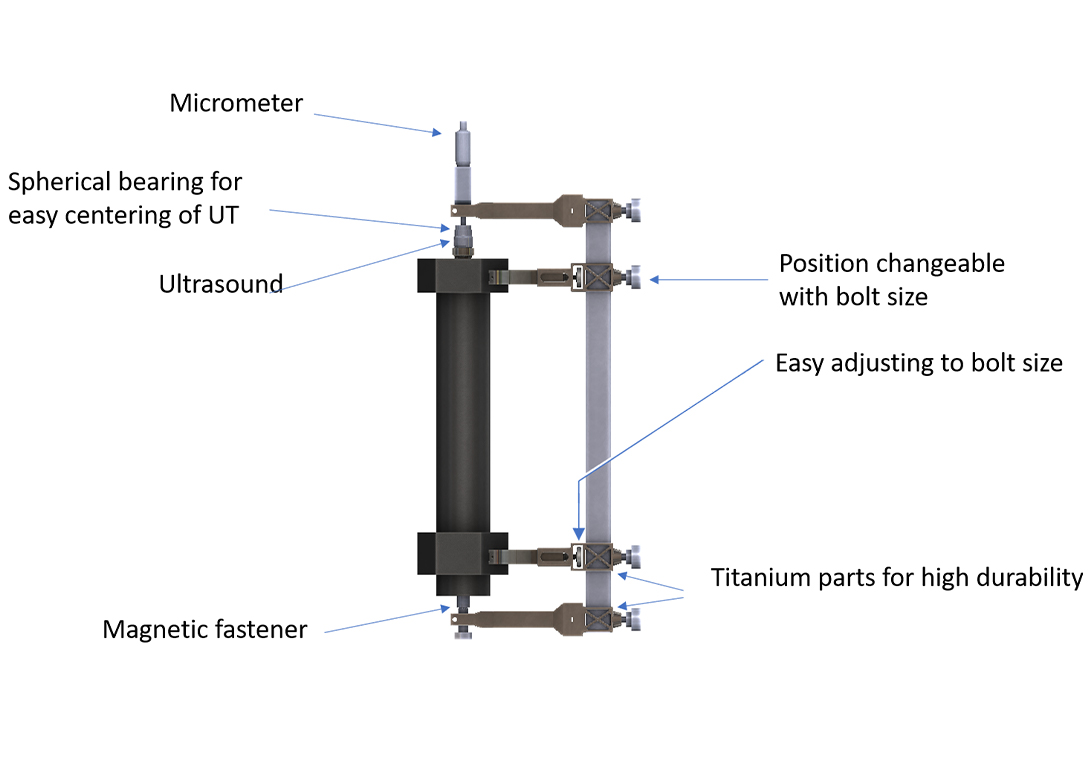

Each manufacturer provides service instructions that detail when preventative maintenance should occur. This maintenance work can be time consuming and cumbersome as the tightening tools are often large and heavy and may not be optimal for health and safety. Furthermore, maintenance can be costly as the tools and the subsequent wear and tear resulting from retightening can be significant. Capable of checking more than 100 bolts every hour, the Bolt-Check tool is light and handheld and thus offers significant health and safety improvements. Maintenance costs are significantly reduced as only the ultrasonic sensor head gets worn over time.

“An offshore wind turbine standing idle can cost as much as US$8,000 a day,” says Selmer Nielsen, senior project engineer, R&D A.S. “Multiply that by 200 for a good-sized offshore wind park and the costs quickly become sky-high. With the Bolt-Check tool, we can reduce the costs of preventative maintenance as the service time can be halved. Because the turbine is back up and running quicker, it can generate energy and therefore money sooner. That is a simple cost-saving calculation.’

Unlike other ultrasonic-based systems, the Bolt-Check tool does not require specially manufactured bolts but can be used with any bolt. Bolt-Check can be implemented at a cost of three to four euros per bolt. This compares to specialized bolts costing 10 times that or more, depending on the bolt size, that are required for use with competing systems. A unique traceability tag is added to each bolt in the Bolt-Check system, providing a detailed documentation trail that includes the location of each bolt as well as its service and maintenance schedule.

As the number of wind power plants increases year-on-year, so does the need for service technicians, which means their time is a scarce resource. Using the Bolt-Check tool, valuable manpower can therefore be used more efficiently since the time spent on bolt inspection is halved.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.