Specially designed to deliver safer, fast and more cost-efficient high torque bolt tightening for critical applications in the energy sector, Atlas Copco recommends its range of cordless smart battery nutrunners, SRB HA.

Installation and maintenance processes carried out using hydraulic wrench methods, on wind turbines for example, can be expensive and time-consuming. But Atlas Copco insists using the company’s proven tensor motor technology these processes can be completed faster and in a more cost-efficient way.

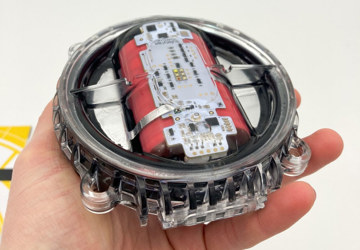

The SRB HA smart battery nutrunner is equipped with a dual trigger, designed to minimise the risk of finger pinch injury. Powered by a 36V li-ion battery, the tool is equipped with charging and health indicators. The single operator tool has a torque rating of up to 4000Nm and an internal torque transducer for maximum control and reliability. Clear operator feedback is provided with multi-functional LEDs, displaying OK/NOK status messages based on torque and angle readings.

With three models available, the entry level SRB HA Digital version has a ‘Set and Go’ function, so it’s ready for use straight out of the box. The Smart and Connected models feature an internal WIFI server, allowing the tools to be linked to any mobile device. This enables torque, angle and batch data collection without the need for additional software. For ultimate functionality and process control, the SRB HA features an accessory bus for a barcode scanner and can also be integrated into overlying systems for live data feed and analysis.

“By combining market-leading safety and performance with mobile connectivity, the SRB HA enables operators to take the smart factory into the field, making it the world’s most advanced and productive battery nutrunner. Being able to control and measure torque in real time with precise accuracy adds significant value to customers operating in challenging environments, as it not only improves safety but also reduces time spent on tasks and saves money. This frees up operators to work on different applications and we believe some companies could save over £40,000 per year in direct costs alone,” says James McAllister, general manager, Atlas Copco Tools and Industrial Assembly Solutions.

“Atlas Copco’s launch of the SRB HA range represents an innovative addition to our portfolio of smart tooling solutions, in pursuit of zero-defect assembly and maintenance. This superior level of traceability and data-driven insight is a real asset in helping companies improve both human and business performance, which is all the more compelling in the current economic climate.”

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.