Specialinsert Srl prides itself on providing innovative fastening systems for every application and in all materials – enabling it to establish itself as a key supplier in niche markets around the world.

Founded in 1974 the company has three sites in Milan, Venice and Turin – all of which have their own sales office. The production and main warehouse is based in Venice and the headquarters, including the export department, is based in a new site in Turin, which was opened in 2014. The Venice and Turin operations also include testing laboratories.

The factory in Venice has two main production lines for cold forming parts and there are also turning machines, milling stations, CNC machines for special parts, as well as machines for secondary operations and a heat treating station. This enables Specialinsert to produce a wide range of fastening systems for applications in sheet metal, wood, plastics and composites.

“From the beginning it was our founders’ policy to keep the production based in Italy and this will not change for the future,” states Federico Sarti, export manager at Specialinsert. “Of course producing in Italy can be hard, with labour costs being high. This makes it difficult to offer competitive prices against Far Eastern companies producing standard products. That is why we focus on specific applications and newer technology. A big advantage we can offer customers is we have production, technical offices and R&D all based in Italy. This means we can work with customers on products that require a lot of expertise and high technology.”

In the last ten years the strategy of Specialinsert has been to further expand its exports and reach new niche markets, as well as conduct further research and development into innovations. “At Specialinsert we have always been known for our innovations and introducing new products to the market,” points out Federico. “In fact we already have 10 patents registered for specific products – with more planned for the future.”

A significant part of the company’s ability to introduce innovations is its R&D department. “Our concepts come from our R&D team working with both our customers on new solutions to applications, as well as by the internal work we do on particular markets,” explains Roberto Amerio – responsible for R&D.

Federico adds: “We are able to collaborate with customers on new products or applications where they are having difficulty. This is part of our 360 degree service – where we work with the customer before, during and after the sale – which is something our customers appreciate a lot.”

An area in which Specialinsert has conducted a lot of research is the composites world, where it has seen a lot of success – especially in carbon fibre. “Carbon fibre is a very popular material for a variety of applications due to the security it offers as it is strong and solid,” points out Roberto. “Only a few years ago using carbon fibre was expensive and complicated. Now the price has reduced a lot, so much it is now used in middle/low level cars, as well as boats and furniture.”

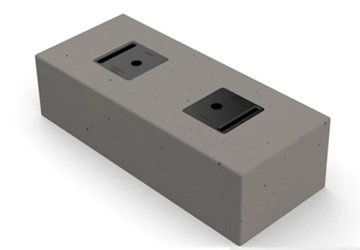

A prime example of Specialinsert’s unique capabilities for composite applications is the TC/SC/1, which is a rivet nut that works both mechanically and chemically in sandwich panels. “We saw there was a need in the market to have fasteners for sandwich panels that did not rely solely on chemical products and helped to simplify the installation process,” explains Roberto.

“The TC/SC/1 works both mechanically and chemically because it deforms into the skin like a traditional rivet nut, but it also works chemically because the user fills the hole using adhesive before they insert it. Once the adhesive is cured it makes a solid connection with a strong performance in terms of pull-out and torque – more than other fastening solutions.”

Federico adds: “We introduced this product because we found that on the market there were only solutions using solely adhesive. We wanted to introduce something new. The TC/SC/1 is a modular system that can be used with sandwich panels from 10mm thickness up to whatever size the customer requires. It is also a very flexible system and can be used with different materials, including when the internal core of the panel is honeycomb or foam.”

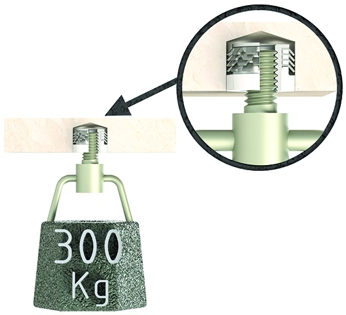

Another product Specialinsert has introduced for composites is the KEEP-NUT® – a self-locking mechanical anchor that works on any solid surface. “The KEEP-NUT has one the best growth rates out of all of our products – especially abroad,” points out Roberto. “It is a patented product and has been used for several projects across the world. The system works in a very flat and round hole – there is no need for an undercut, which is a big advantage for the customer. It means the hole can be drilled a lot quicker and the operator can use a standard tool. The KEEP-NUT also has special teeth and washers that anchor the product into the material and it provides the same pull-out strength and requirements as other products.”

Roberto continues: “Another advantage is once it is installed it is flush with the material, so the user can install it and transport it with the panel without any worries regarding storing or stocking the panel.” Specialinsert does not just focus on composites, it also develops new products for metal sheet/plastics, wood and a range of other specialist materials. A recent development is the self-locking DEFORM-NUT®, which is for applications with very high vibration. “We have found customers are talking to each other about our products and their benefits, which is a good thing for us because it shows how well accepted our products have become and the good reputation they have gained in the market. You cannot beat the value of ‘word of mouth’,” says Roberto.

“The strategy of the company from the beginning was not to concentrate on the big fastener markets, but to focus on the specialised markets, on quality, on the needs of niche markets, and the after sales service for the customer,” mentions Federico. “Now that we have the experience, knowledge, and products, we are looking to work with more companies on specific and advanced solutions.”

Specialinsert is able to supply customers around the world and is always looking at new markets to target. “In the last five years we have been more proactive in targeting new markets,” explains Federico. “We are no longer waiting for customers to come to us, we are going after them and we are having a lot of success. We have recently received a a European Technical Assessment for the KEEP-NUT (ETA – 15/0615), which will open up new opportunities and in the next couple of years we will apply for ISO/TS 16949 for the automotive industry, which will enable us to work with automotive suppliers.”

Specialinsert is already experiencing growth with turnover increasing 8% in 2015 and the company reporting that in the first six month of 2016 sales have increased by over 10%, compared to the same period in 2015. “Our export business is growing,” states Federico. “We have entered new markets such as the USA, which is a good market for us. Another market that is of interest for us is the Middle East – especially the United Arab Emirates. At the moment 15% – 20% of our sales is represented by exports. We would like to see this increase to closer to 50% and with the new products we are able to offer – in niche markets – we believe this is definitely achievable.”

The company’s ability to introduce new products and target specific applications and markets puts it in a very strong position to continue to grow. Through its R&D department it will also be able to focus on the fixing materials of the future and ensure it is able to provide the fastening technology to new solutions.

“There are new materials everyday and they can all fit under the umbrella of composites,” concludes Federico. “There is always a new mix of materials that offer different benefits and will be lighter and more resistant. It is important for us that we are at the forefront of this sector and we continue to develop new products and applications. Composites will be the future and we are ready.”

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.