Aquamarine Power has ordered RotaBolt® measurement technology for its Oyster 800 wave power project, which captures the energy in nearshore waves and converts it into clean sustainable energy. The fasteners will be fitted to an underwater flange that is part of the system’s main 'water hydraulics'.

Richard Montague, lead mechanical engineer, commented: “There were two main reasons why we ordered RotaBolt® technology. Firstly, we needed to be confident that we were achieving the correct bolt tension on this pipe flange to assure its operational integrity. We also wanted to make maintenance checks as simple and quick as possible. Through experience of using RotaBolt technology before joining Aquamarine Power, I hope our divers will be able to carry out checks for correct tension without re-torquing. This will be a significant maintenance benefit.”

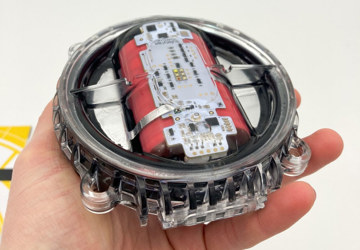

The technology incorporated into each RotaBolt fastener assures that the correct tension is achieved at installation and then throughout the life of the bolted joint. The design features a RotaCap on the top of the bolt, which allows for instant fingertip checking of correct tension – making it ideal for applications where operators are looking for operational integrity and also maintenance savings.

The Oyster 800 project is situated off the Orkney Islands and has been operational since 2012. Essentially it is a wave powered pump consisting of a buoyant, hinged flap that is attached to the seabed at depths of between 10m and 15m, around half a kilometre from the shore.

The hinged flap, which is almost entirely underwater, pitches backwards and forwards in the nearshore waves. The movement of the flap drives two hydraulic pistons, which push high pressure water onshore via the subsea pipeline to drive a conventional hydro-electric turbine.

The project is being continually refined and improved by Aquamarine Power and it is expected that next winter’s weather will provide a fuller testing of RotaBolt’s ability to assure integrity, before a final assessment is made next spring. The hydraulics system has a number of flange connections, which could potentially also benefit from RotaBolt technology.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.