From protecting valuable assets to protecting lives, radio-frequency identification (RFID) has many different industrial applications. Take the oil and gas sector, where everything from asset management to ensuring testing is up to date on safety equipment can be done with RFID. RFID from HellermannTyton is available in a range of frequencies, each with its own benefits.

Low and high frequency RFID are great for making sure the testing is up to date on safety equipment such as shackles and chains. Because low and high frequency RFID require close proximity to read the data, they are great to use where precision is key.

“RFID tagging works in a similar way to barcoding but with some key differences. Barcodes can be easily damaged, rubbed off or hidden from the line of sight. RFID tagging addresses all of these issues. The tags are read via radio frequencies so a line of sight is not required for an accurate read. And because the chip is housed in a strong resin there is very little chance of it becoming damaged; in fact, by using metal RFID cable ties, RFID tagging becomes a very resilient way of cataloguing equipment,” comments Nathan Bennett, associate product project manager at HellermannTyton.

Each RFID tag has a unique 16 digit code as part of a global tag database and can be used to link back to a pre-existing in-house database, to catalogue equipment and log testing periods. Some information can also be stored in the tag itself, meaning that even without access to a database or internet connection you can check that safety equipment is within its test date range.

RFID is also available in ultra-high frequency which increases the range at which a tag can be read. This is ideal on oil rigs, for example, where the parts that need tracking and maintaining can be meters away. With RFID you can simply point the ultra-high frequency reader in the general direction and it will provide a list of all the RFID tags in the vicinity.

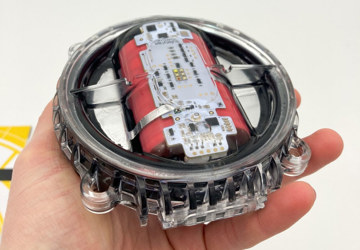

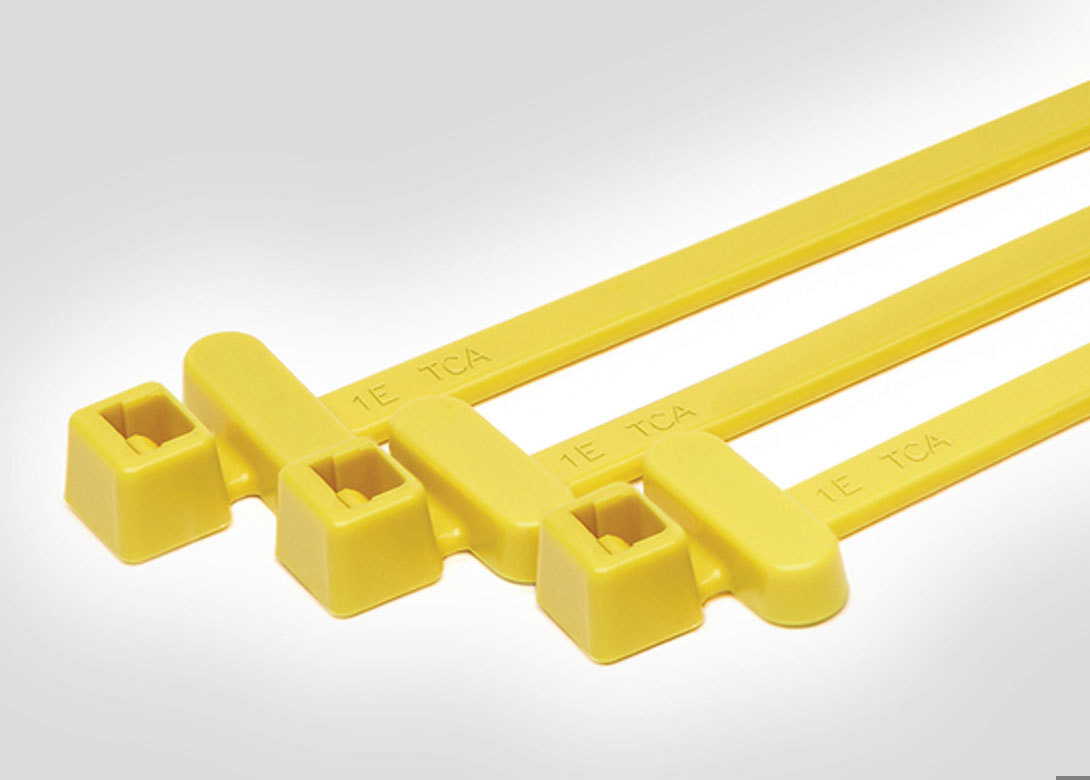

RFID tags from HellermannTyton are available in a range of formats and in low, high and ultra-high frequencies. Both nylon and metal cable ties are available; as is a cradle solution which can be added to existing cable ties or the hextag, used where a cable tie solution is not the best option.

Due to its in-house capabilities, HellermannTyton is able to offer bespoke solutions.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.