The HEICO Group, based in Ense in Westphalia, Germany, has been at the forefront of fastener technology since its inception well over 100 years ago. A truly international organisation with over a dozen subsidiaries and employing over 430 people, the group is well placed to provide the highest standards of bolt security to a worldwide customer base.

The family owned business has a long tradition of forming metal, starting out producing upholstery and furniture nails before expanding into cold forming of industrial fasteners, particularly for the automotive industry. After passing on the management of the family-held company to the fourth generation an innovation drive saw the company launch the HEICO-LOCK® wedge lock washers.

As Jan Bernd Heimann, company director of the HEICO Group, explains innovation has always been at the core of the company’s business model, “Both in terms of the products we develop and the unique production processes and in-house developed tooling we use, innovation is key to our success. This innovative approach has seen the introduction of our HEICO-LOCK wedge locking range and also the unique HEICO-TEC® tension nut”.

The HEICO-LOCK® system was developed by the company to counter the effects of dynamic loads and high vibration causing loosening of bolted joints by self-rotation and consists of a pre-assembled pair of washers that have inclined cams on the inside and radial teeth on the opposite sides. When a bolt is tightened the external radial teeth embed themselves in an interlocking fashion with the respective mating surface. As the angle of the internal cams is greater than the angle of the thread pitch any movement across the cams increases the pre-load force and effectively self-locks the bolt. This same functioning principle forms the basis of HEICO’s other wedge locking products.

With the Ring-Lock system an outer plastic ring ensures that the individual washers are permanently held in the correct position even after disassembly, thus ensuring effective operation even when used by non-specialized operatives.

The one piece HEICO-LOCK® wedge lock nut combines the HEICO-LOCK® wedge lock washer with a flanged nut. The riveting of the connection between the wedge lock washer and the flanged nut creates a one piece design that removes the need for a separate washer, providing a reliable, faster and cost-optimised bolt security solution.

The new HLK washers deliver anti-vibration security for HV sets according to DIN EN 14399-4 and DIN EN 14399-8. The HLK washers are chamfered on the internal diameter to ensure optimal surface contact with the increased under head radius of HV bolts and is approved by the German Institute for Structural Engineering (DIBt).

The latest addition to the HEICO-LOCK® range is the Combi-Washer which has an inner locking ring with inset tabs that grip onto the bolt thread. With easy mounting and permanent connection, thanks to the inset tabs, the combi-washers provide real flexibility as they can be combined with all commercially available bolts as well as being supplied completely pre-assembled on request.

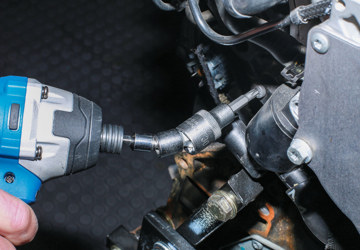

HEICO’s bolt security expertise has also seen the development of the HEICO-TEC® tension nut for use with large bolted joints. With HEICO-TEC® no electric, hydraulic or pneumatic tools are needed for installation, all you need is a torque wrench. The pretension force of the large main thread is distributed to many smaller pressure bolts meaning a conventional torque wrench can be used to achieve the correct pretension force, eliminating the need for complex, bulky or heavy tools and making securing large bolted joints more convenient and easy. Also HEICO-TEC® meets all the requirements of ISO 898-2 which enables you to easily replace any hex nut from the same strength class while also offering all the advantages of a hand-tightened nut.

With ISO 9001:2008 and ISO/TS 16949:2009 accreditation, along with product approval from organisations such as Deutsche Bahn and DNV, the groups commitment to quality is further underlined by the creation of an in-house laboratory for the testing of bolt fastening systems, as Jan Bernd Heimann explains ”Our fully equipped laboratory includes a wide array of test rigs, measuring equipment and the most up to date measuring software, all of which is operated by our experienced and highly skilled lab team. We can provide clients with extensive test services, research & development support and quality control reporting as well as customised tests to our client’s individual requirements”.

Jan Bernd Heimann concludes: “The customer is central to HEICO’s philosophy as we aim to provide all our customers’ needs from one source. This includes bolted joint product development, in house lab testing, engineering and bolted joint expertise, all backed up by certified production quality. Our flexible processes allow fast response to customer requirements whilst providing our customers with sophisticated solutions for both standard projects and specific concepts”.

“With continual development and innovation at the heart of the HEICO philosophy the future of bolt security is in safe hands.”

Will joined Fastener + Fixing Magazine in 2007 and over the last 12 years has experienced every facet of the fastener sector – interviewing key figures within the industry and visiting leading companies and exhibitions around the globe. Will manages the content strategy across all platforms and is the guardian for the high editorial standards that the brand is renowned.