Harrison Silverdale, supplier of specialised fasteners to all industry sectors, has a wide range of parts predominantly used in plastic mouldings and sheet metal fabrications. These consist of threaded inserts, spring steel fasteners, self-clinching and turned parts.

As well as its standard range Harrison Silverdale has an in-house design team who work closely with clients in the development stages of new projects. The company was recently approached by an existing client, who is a tier 1 supplier of injection mouldings to the automotive industry.

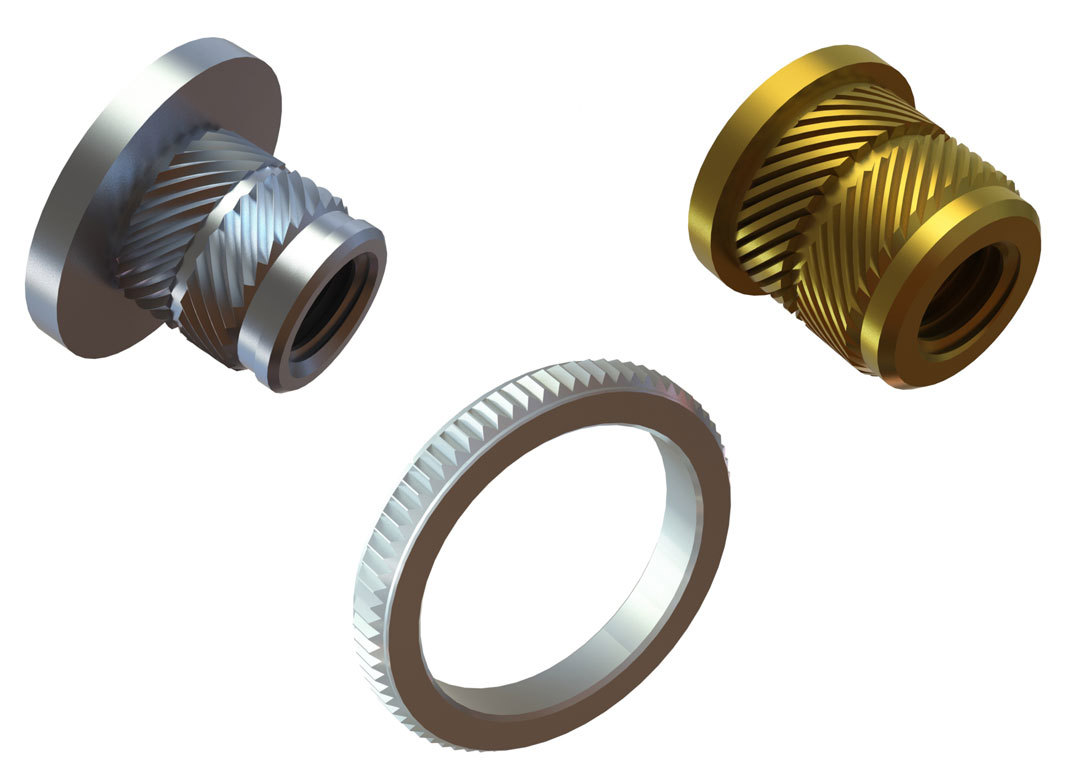

They client needed support on a new project which required a number of special components to fasten a plastic injection moulding to a vehicle currently in production. The moulding was designed to replace an aluminium bracket as a weight and cost saving exercise. It required a number of M8 and M6 threaded inserts and six compression limiters in various locations.

The compression limiters are steel rings used to strengthen weak area’s when bolting to the vehicle. It was pointed out early in the design stage that the M8 inserts would be in contact with the aluminium body in white on the vehicle so they were specified as aluminium to prevent any possibility of galvanic corrosion which can occur when dissimilar metals are in permanent contact. The client needed a large flange diameter to provide a good surface bearing area to spread the load of the clamping force.

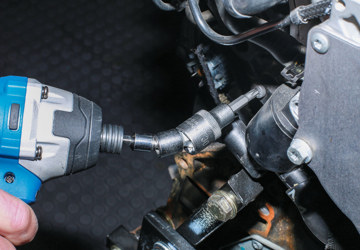

Due to the high torque loads required during the assembly of the bracket to the vehicle, Harrison Silverdale recommended parts from its oversize range to achieve the extra performance. These are basically inserts with a larger body diameter so have better retention in the moulding. The serial production inserts would be heat staked after the moulding process by a special purpose machine but due to a delay, Harrison Silverdale was able to loan one of its manual heat staking machines for the initial build.

Harrison Silverdale worked closely with the client’s engineering team from day one sharing CAD data, prototype samples and initial pre-production parts resulting in the successful completion of the project in a tight timeframe. The parts are now in full production and look like being carried over onto new vehicle programmes.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.