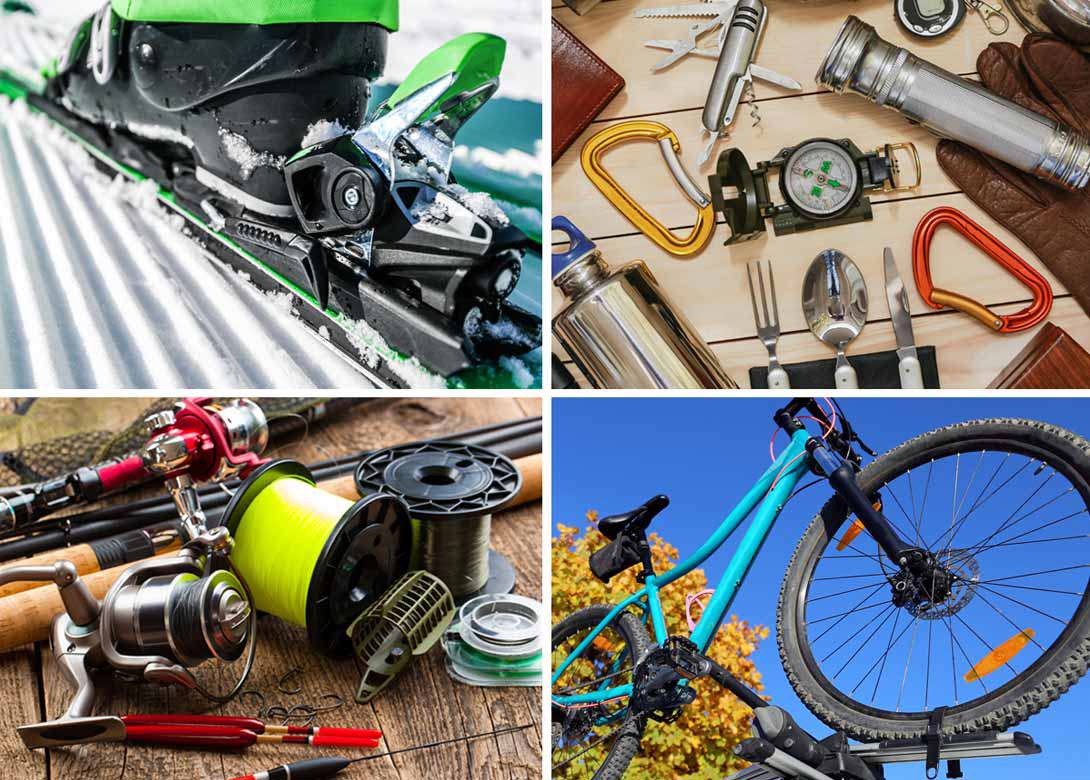

The performance demands of the outdoor recreational gear industry requires parts and components that combine lightweight, extreme durability, high strength, corrosion and UV resistance, and offer the highest levels of reliability.

Boker’s Inc delivers 100 years of application solving experience for OEM challenges, including the industry leading range of non-standard washer and spacer sizes, thickness, profiles and materials, plus custom, made to order washers, spacers, shims, stamped parts and components, manufactured for hundreds of products in the outdoor, adventure sports and recreational industries.

Along with the millions of possibilities offered by its extensive range of non-standard sizes, industry leading brands in the outdoor equipment and recreational gear markets rely on Boker’s for manufacturing of their proprietary parts, custom shapes and specialised requirements. Boker’s has unique part and component fabrication experience in numerous OEM outdoor product applications such as navigation equipment and instruments; cameras, scopes and binoculars; flashlights and lanterns; outdoor power equipment; canoes and kayaks; communications systems; and portable solar power systems.

Whether an OEM is looking for formed or fender washers that can be used in tents or miniature specialised washers for the needs of complex fly fishing reels, Boker’s is the trusted partner to turn to. In addition to washers and spacers, Boker’s can provide simple to complex custom stamped components used in a variety of product applications ranging from snowshoe cleats to camping stoves.

OEMs recognise the unique qualifications, capabilities and quality offered by Boker’s, including over 32,000 non-standard washer sizes that can be manufactured to exact specifications with no tooling charges. Custom washers are available in outside diameters ranging from 0.080 inches to 12 inches. Boker’s custom stamping offering includes flat blanking and piercings in sizes up to 12 inches x 12 inches, complex metal forming in thicknesses from 0.005 inches to 0.190 inches (varies by material), and deep draws up to 3 inches and 8 inches in diameter.

Boker’s offers immediate access and experience with over 2,000 common and hard to find exotic material choices to meet the needs of the outdoor recreational market, including metallic or non-metallic options, low carbon sheet steel, numerous super alloys, stainless steel, aluminium, brass, beryllium copper, phosphor bronze and nickel silver. Non-metallic materials available include ABS, acetal, polyester, nylon, MD nylon, polycarbonate, fiber, polyethylene and NEMA-grade laminates.

Boker’s is also equipped with in-house secondary operations to meet the demanding finishing requirements of the industry including deburring, tapping, reaming, counterboring, and spotfacing, plus trusted local vendors for heat treating, plating and non-destructive testing (N.D.I.). Boker’s also offers 3D rapid prototyping and functional prototyping, plus co-development capabilities to help OEMs efficiently solve their product engineering challenges quickly.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.