With the global market for electric vehicles (EV) growing at approximately 60% per year since 2014, the current narrative points to an automotive industry that is set to enter a period of wide ranging and transformative change. However, if companies want to have a successful, long-term future then key strategic decisions need to be made with caution over the next 18 months as sales continue to shift and regulations tighten.

As a full service provider with a global reach from the USA to Asia and Europe to the UK, TR Fastenings is consistently developing established relationships with partners and customers throughout the world within the automotive space. It is in a solid position to respond to global developments and is ready to play a significant role in shaping the industry as it progresses forwards.

As such, TR was recently invited by The Society of Motor Manufacturers and Traders (SMMT), Santander Corporate & Commercial and the Department for International Trade (DIT) to be part of a delegation of UK suppliers to address 95 companies in Warsaw, Poland, to discuss the growing international capabilities of TR Fastenings and how it can contribute to the wider evolution of the automotive sector.

Poland has a large base of automotive suppliers at each stage of the supply chain and presently, automotive manufacturing is one of the largest industrial sectors in the country, accounting for 11% of sold production value in this part of its economy.

Driving OEMs into the future

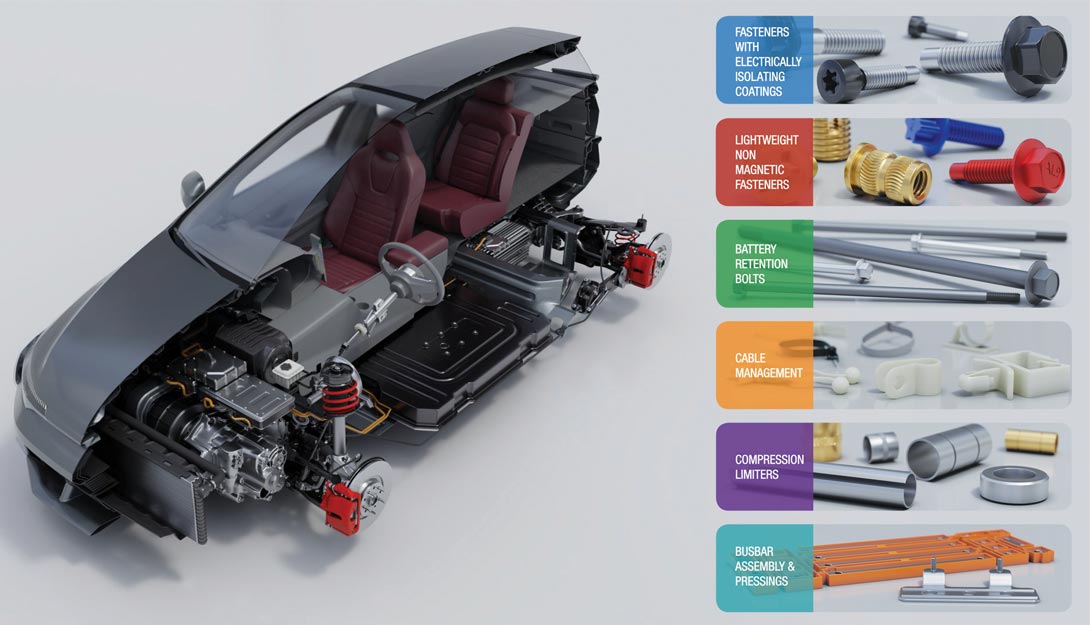

Automotive OEMs face some serious challenges. TR supplies over 10,000 different fasteners annually to tier 1s in the automotive sector. These cost-effective parts are predominantly manufactured, according to TR’s zero defect philosophy, at its flagship manufacturing plants in Malaysia and 2 factories in Taiwan – the gateway to its Asia/Pacific OEM relations.

The expectations of the customer have changed. Due to the waning of product differentiation and a general increase in vehicle quality throughout the sector, customers are becoming less loyal to a specific brand and expect more high-end features to be standard.

However, many automotive customers have specific needs in terms of product and in order to help customers maximise a component’s full potential, TR’s team of Application Engineers work closely with its tier 1 customers’ design engineers. TR has built a reputation as the ‘go to’ company for support and our technical team are happy to arrange on site visits for problem solving or a like-for-like cost-saving alternative product development or the design of a totally new component.

“We work closely with our customers to localise their parts and supply base and offer lean supply solutions close to their facilities. Our global presence and market expertise enables us to support tier 1 companies on an international basis, leveraging volumes and simplifying supply chains,” comments TR.

For further information contact TR’s global automotive team - automotive@trfastenings.com

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.