The fasteners most commonly prone to galling when tightened are made of stainless steel, aluminium or titanium. Stainless steel fasteners are available in austenitic, ferritic and martensitic grades, with austenitic grades of stainless steel fasteners usually used in the industry. The stainless steel material has a chrome oxide layer, which protects it from corrosion.

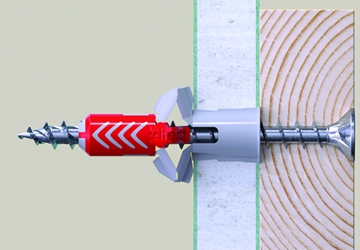

Galling is seizing or abrading of the threads, in which either the joint elements jam during the assembly or threads get damaged. It is also known as local cold welding (frictional bonding) of the thread flanks. It is generally formed when the thread flanks rub against each other for an extended period of time

Ref: FFT150824

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.