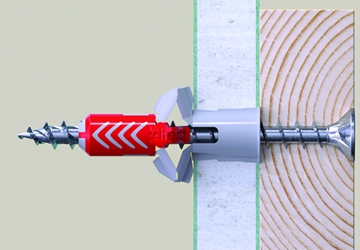

fischer has introduced a new solid rail system (FMS), which makes secondary steel construction unnecessary for heavy installations in technical building equipment as well as in industrial and plant construction.

Pipeline support require their own planning and prefabrication and often leads to delays due to construction tolerances during on-site installation. With the FMS, heavy cable systems can be implemented flexibly and efficiently. fischer states that using its heavy-duty system allows for up to 30% in cost savings thanks to reduction in construction and assembly time.

Using FMS, time-consuming alignment with cutting and welding on site is no longer necessary – and at the same time there are no associated risks such as the occurrence and inhalation of harmful dust. Likewise, there is no need for an additional coat of paint after assembly. The mounting structure with the FMS weighs less overall and the support structure can be completely erected on site.

The company also offers the FMP, equipped with square hollow profiles that reduce the weight compared to steel constructions and are easier to handle on the construction site. The rail profiles are provided with shaped holes on all sides, which enable the safe, error-free and form-fitting assembly of the construction elements. Also, the universal connectors allow simple changes to the construction, allow on-site alterations.

The hot-dip galvanised product range ensures processing on the construction site without subsequent coating. This also helps to make the assembly process quick and easy. Compared to the average zinc layer thickness of around 40μm, the hot-dip galvanising of at least 75μm of the FMP mounting profiles is almost twice as high, thus increasing the average protection period.

Becca is the latest member to join our team and is eager to get stuck into the world of fasteners. She brings an enthusiastic and fresh outlook on what we do editorially and will be leading our social media activity – including sourcing material, editing articles and posting online.