Harrison Silverdale is currently working in partnership with a leading automotive moulder on a new battery box application for a major UK automotive manufacturer.

The box houses a battery that powers a compressor for the self-levelling suspension system in the rear of the vehicle. It consisted of an inner and outer moulding, a large steel pressing and a heat shield.

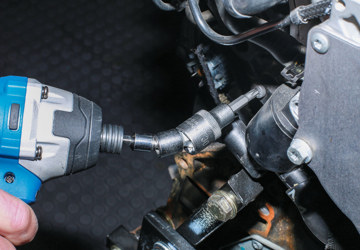

After receiving basic CAD models of the fixings Harrison Silverdale refined the designs and returned them for approval. Due to the different materials and the configuration of the box, the range of fixings was quite diverse. They included two different M6 brass inserts, two sizes of compression limiters, a large diameter flat washer, a push on fix and an M6 x 30 bolt. Harrison Silverdale’s extensive product range meant it was able to supply all the component parts to its customer – providing them with a single source solution.

Harrison Silverdale points out that only two of the seven fixings for the application were standard - the bolt was changed so an existing part could be utilised and a push on fix to hold the heat shield in place. As development progressed it became apparent that standard M6 brass inserts would not withstand the high torque requirement. Harrison Silverdale therefore developed two bespoke inserts with oversized bodies. The compression limiters also had to be designed due to the special geometry. Prototype samples were manufactured and submitted for testing until the final designs were signed off and bulk production could commence. The project was completed within the tight time constraints ready for the vehicle launch at the end of 2012.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.