The CFRP production team at BMW Group Plant Landshut in Germany has won the JEC Europe Innovation Award 2021 for the customised carbon spats of the MINI John Cooper Works GP car. The C-DS compact dispensing system from RAMPF Production Systems was used to bond the high-performance carbon components.

The MINI John Cooper Works GP needs just eight minutes to complete a lap of the legendary Nürburgring Nordschleife racetrack, which proves that this premium small car does not just look sporty – it is also impressively fast.

The vehicle’s large and strikingly designed spats contribute to both its spectacular appearance and the impressive lap time, and were developed and industrialized by the experts at BMW Group’s Lightweight Construction and Technology Centre (LuTZ) in Landshut.

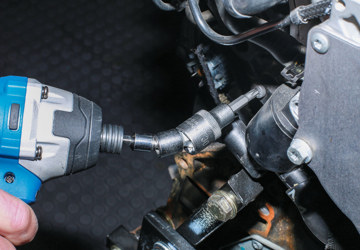

During the fully automated process, the spats are wet-pressed onto injection-molded plastic inner panels. The two-component adhesive used to bond these parts is applied by the C-DS compact dispensing system from RAMPF Production Systems in a process that is also fully automated.

RAMPF’s technology ensures the reactive polyurethane adhesive system is applied rapidly and with outstanding precision. The modular design of the C-DS means it is easy to integrate into the overall production line, while the continuous monitoring of pressures, temperatures, and fill levels with graphically supported process overviews ensures maximum reliability.

The C-DS is equipped with the MS-C 100 mixing system developed by RAMPF Production Systems. This dynamic compact system covers a dispensing output range of around 2 to 120 g per second. Its small external dimensions give the mixing system greater flexibility for applying complex component contours, which is a key advantage when it comes to the spats.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.