By Dr Bill Eccles, Bolt Science

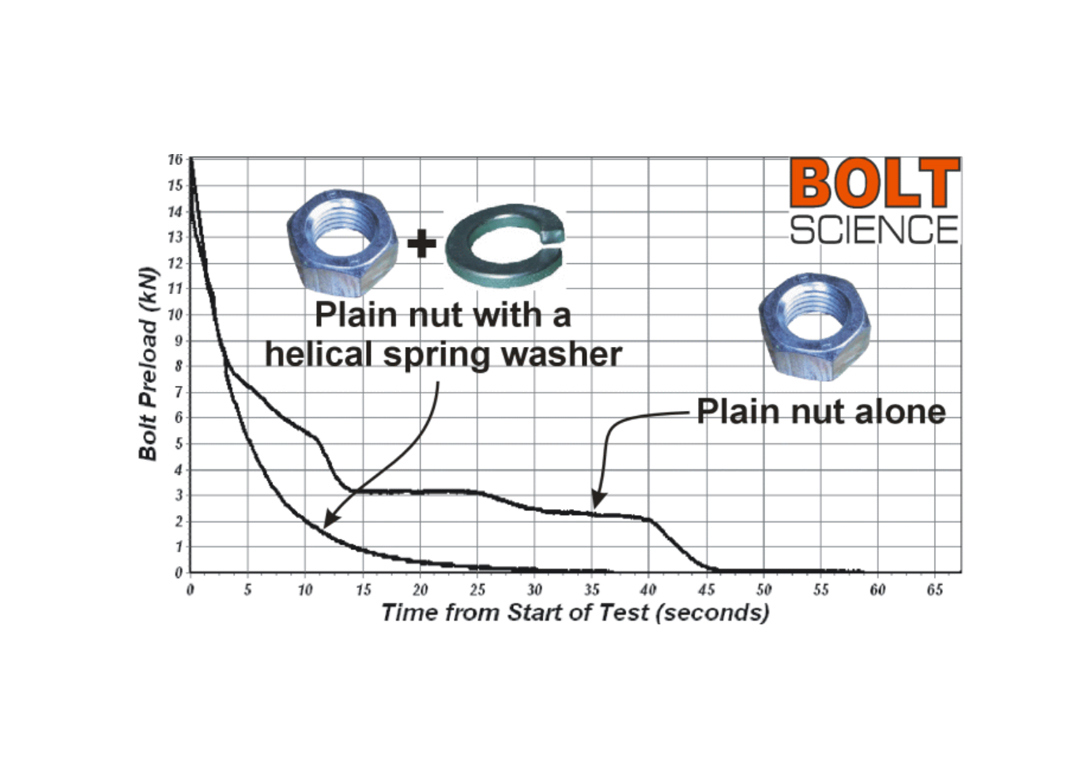

Helical spring lock washers have been in use for well over 100 years. They are still used on many applications in the belief that they will ‘lock’ the nut/bolt to the joint and prevent loosening. Bolt Science has performed a series of tests to illustrate the performance of this type of washer compared to a plain nut by itself.

The body of evidence, based upon both experience and experimental results, is that helical spring lock washers do not prevent loosening and can be shown to actually speed up the rate of loosening in many cases. Junker originally showed in his work published in 1969 that these washers are ineffective in preventing loosening. Joints containing these washers have come loose resulting in structural failure leading to both material and human loss.

A series of tests were performed by Bolt Science to illustrate the performance of this type of washer compared to a plain nut by itself. The results are shown in videos and in the preload decay curve above. The preload decay curve is from the tests shown in the video. The tests were performed on M8 fasteners.

The test shown below is a test on a plain, non-locked nut. Under a Junker test such a nut will readily self-loosen.

A helical spring washer fails to prevent self-loosening. A video of a typical test is shown below.

www.boltscience.com

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.