Alcoa Fastening Systems (AFS) has helped Italian refrigerated truck manufacturer Cold Car SpA significantly reduce its costs by improving the installation efficiency of its low temperature refrigerated truck bodies with the use of the Huck BobTail® lockbolt fasteners.

Based in Occimiano, Cold Car SpA was established in 1968 and now employs 180 people. Manufacturing and installing 2,000 bodies per year, the company has a worldwide customer base, including transporters of ice cream, frozen food, dairy and dry products, which are loaded into low temperature or refrigerated compartments, occasionally divided by fixed or movable bulkheads.

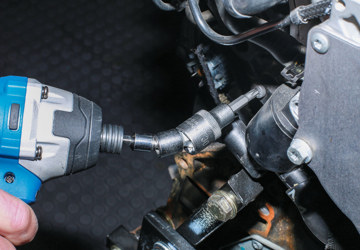

Launched in 2009, the BobTail fastener has been successfully used on a variety of industrial applications to replace standard lockbolts, nuts and bolts, and even welding. Prior to using it, Cold Car welded the body to the truck’s sub frame. Bertone Davide, Cold Car’s research and development manager, explains: “Following a successful prototype test using BobTail supplied by AFS distributor Unifast, we realised that it would work well as a complementary option or completely viable alternative to welding. No pin break in the installation process reduces noise levels in the assembly line, as well as eliminating the potential for rust to compromise the long-term life of the installed fastener.”

“In fact, the use of BobTail in the body to subframe assembly has resulted in a stronger joint and a reduction in welding time by 30%, enabling one welder to work on other special prototype projects. 30 minutes per trailer and approximately 500 hours per year has been saved in overall production time. In addition, the technical information and customer support for the product and tooling provided by AFS and Unifast has been outstanding,” added Bertone.

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.