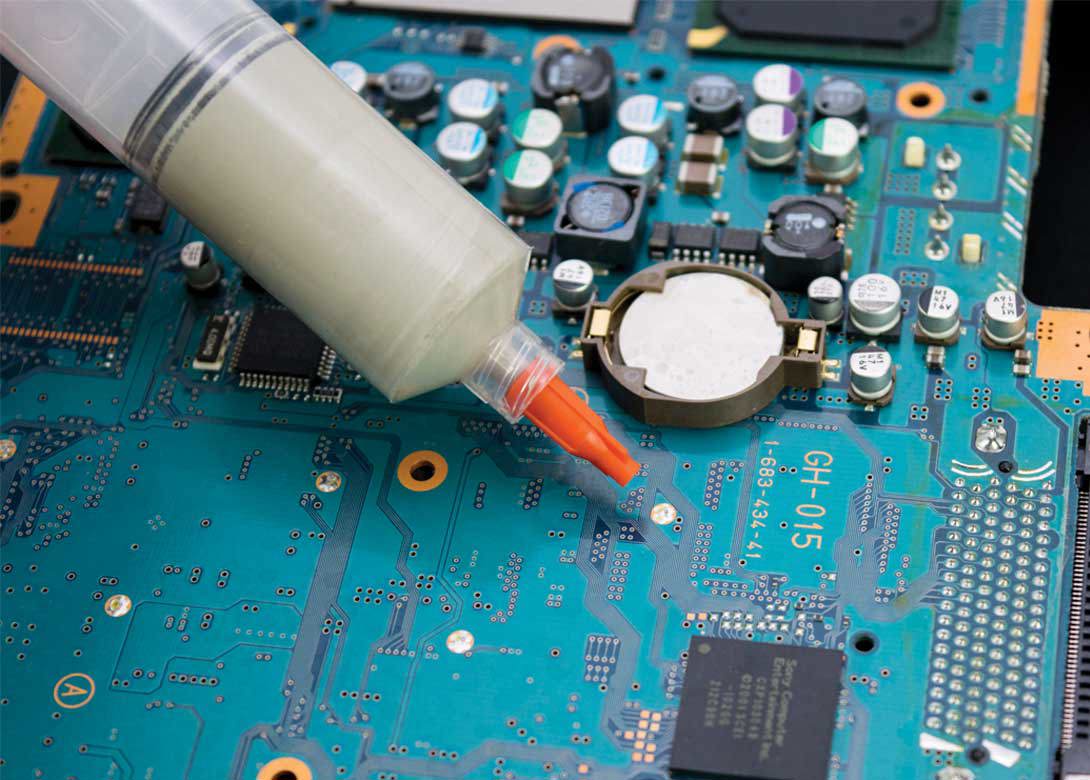

The EP3HTS-LO, a single component epoxy for demanding bonding, sealing and coating applications from Master Bond, has passed ASTM E595 tests for NASA low outgassing.

Ideal for use in the aerospace, electronic, microelectronic and optical industries, Master Bond says its EP3HTS-LO features a silver filler and is electrically conductive with a low volume resistivity of less than

0.001 ohm-cm. It also has a thermal conductivity of 12-15 BTU•in/(ft²•hr•°F) [1.73-2.16 W/(mK)].

Having spent a decade in the fastener industry experiencing every facet – from steel mills, fastener manufacturers, wholesalers, distributors, as well as machinery builders and plating + coating companies, Claire has developed an in-depth knowledge of all things fasteners.

Alongside visiting numerous companies, exhibitions and conferences around the world, Claire has also interviewed high profile figures – focusing on key topics impacting the sector and making sure readers stay up to date with the latest developments within the industry.